NPI, short form for New Product Introduction, means those activities that introduce a new or improved product. It includes the definition, layout, development, prototyping and even the launch of a product. The product doesn’t have any limitations – it can be anything.

It aims to get a final working prototype that can help one to get a faster market. People also call it NPD, short for New Product Development.

Here, the engineer’s work is to keep drafting new concepts for their product until the final prototype is ready, including any required design alterations.

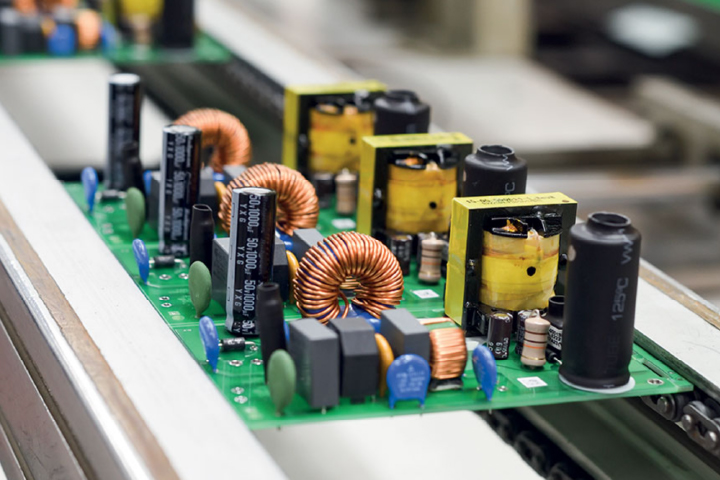

Introduction of new products is a great deal. Electronics contract manufacturers know that NPI (New product introduction) is a must since it helps them to ease the complexities and move forward in the marketing community.