- Home

- About us

- Products

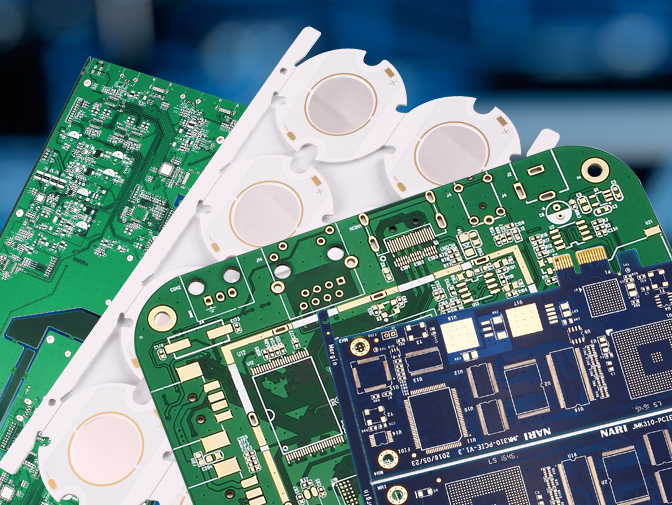

- PCB Fabrication

- PCB Assembly&OEM

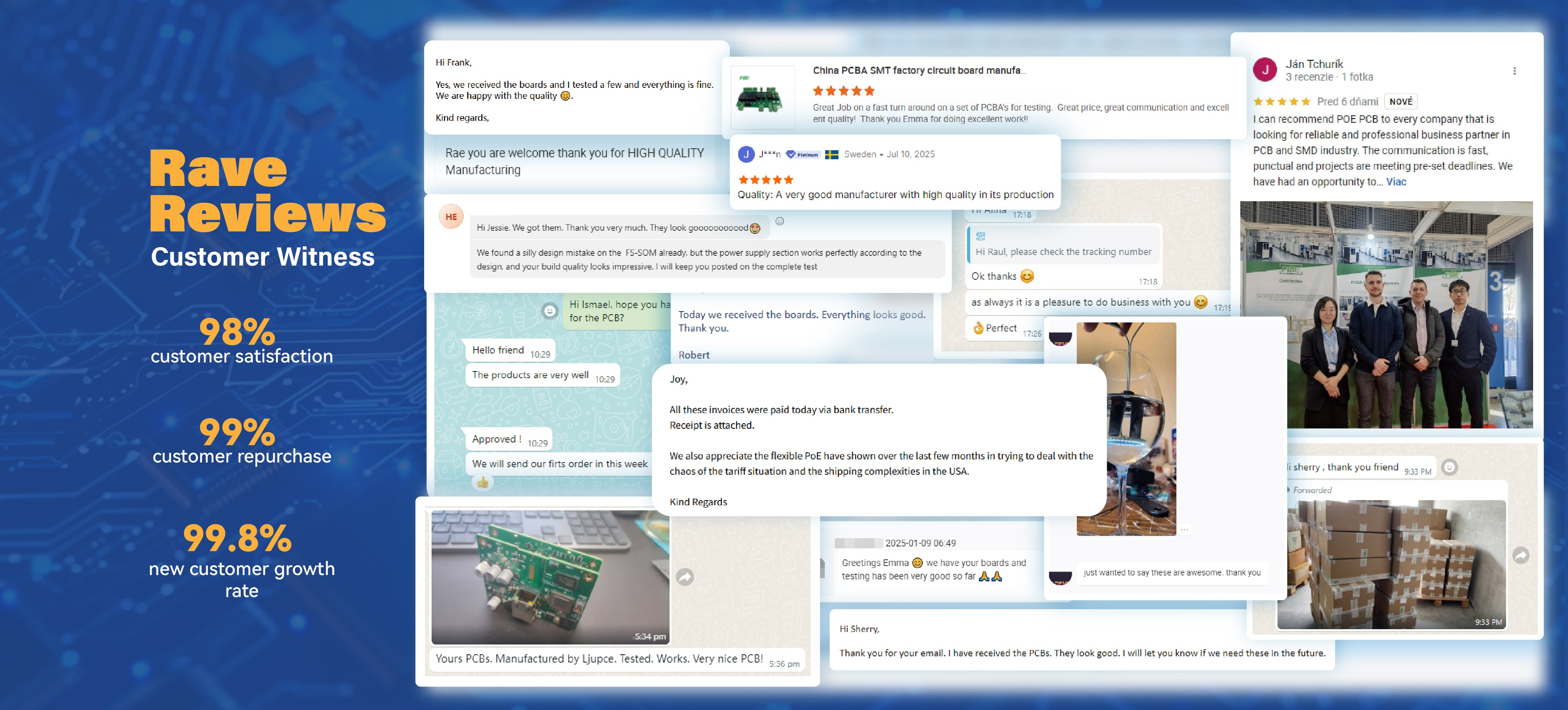

- Quality

- Blogs

- Contact

One-Stop Turnkey PCB Assembly Manufacturer

One-Stop Turnkey PCB Assembly Manufacturer

One-Stop Turnkey PCB Assembly Manufacturer