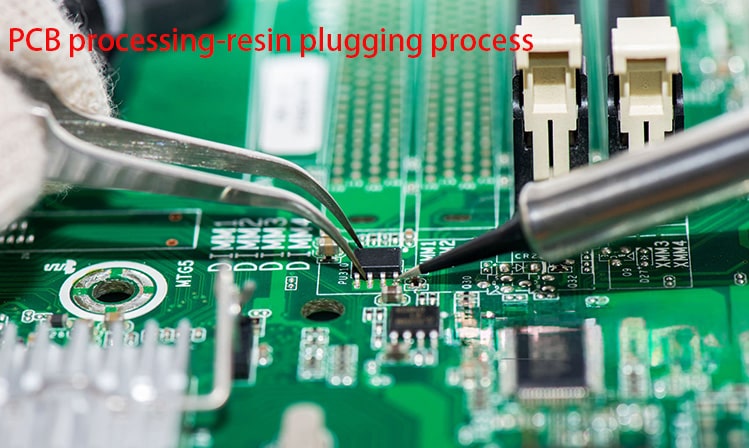

What is the resin plugging process in PCB processing?

As an important part of electronic product manufacturing, the processing quality of PCB circuit boards directly affects the performance and reliability of the entire product. In the traditional circuit board processing technology, the resin hole plugging technology has gradually become a technology that has attracted much attention.

What is the resin plugging process?

The resin plugging process is a method used to deal with excess copper foil holes on the surface of PCB circuit boards. During the circuit board manufacturing process, in order to facilitate the conduction of current, copper foil holes are usually provided on the circuit board. However, due to manufacturing process limitations or design reasons, some copper foil holes cannot be completely filled during processing, which may lead to problems such as current waste and signal instability during use of the circuit board.

The resin plugging process improves the reliability and stability of the circuit board by filling these redundant copper foil holes with resin materials on the circuit board. Resin materials can effectively fill holes in copper foil, allowing current to conduct more smoothly and preventing contaminants from entering and causing circuit failure.

The impact of resin plugging process on PCB production costs,

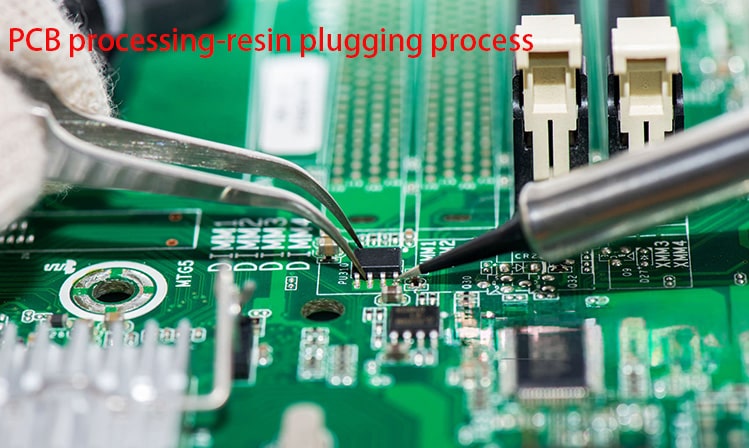

The introduction of the resin plugging process has increased the production cost of PCB circuit boards to a certain extent, but it also brings many advantages, making the overall efficiency higher.

First of all, the resin plugging process can improve the reliability and stability of the circuit board and reduce the problems of current waste and signal instability. This means fewer failures and quality issues during product use, thus reducing repair and after-sales costs.

Secondly, the resin plugging process can improve the antioxidant and moisture-proof capabilities of the circuit board. Filled resin materials can effectively prevent oxygen and moisture from corroding circuit boards and extend the service life of the product.

In addition, the resin plugging process can also enhance the mechanical strength of the circuit board. Filling the resin material can fill up the unevenness on the surface of the circuit board, increase the strength of the circuit board, reduce the probability of damage to the circuit board during the manufacturing process and transportation, and reduce the scrap rate of the product.

In summary, the resin plugging process, as an important technology in PCB processing, has been widely used in the field of electronic product manufacturing. Although the introduction of the resin plugging process will increase the production cost of PCB circuit boards, the advantages of reliability, stability and extended life it brings make the overall efficiency higher. For electronic product manufacturers who pursue high quality and reliability, the resin plugging process is undoubtedly an indispensable part.

In the future, with the continuous development and innovation of technology, the resin plugging process will be further improved, bringing more possibilities and opportunities to PCB processing. I believe that in the near future, we will usher in a new era of more efficient and reliable PCB processing.