SMT basic process steps

SMT patch is an abbreviation for a series of technological processes processed on the basis of PCB. The PCB we have introduced before is a printed circuit board, while SMT is a surface mount technology. It is the most popular technology and process in the electronics assembly industry. Today we will introduce what are the basic processes of SMT PCB assembly patch

The basic process components of SMT include: screen printing, placement, reflow soldering, cleaning, testing, and rework

1. Screen printing: Its function is to print solder paste onto the PCB pads to prepare for component soldering. The equipment used is a screen printing machine, located at the front end of the SMT production line.

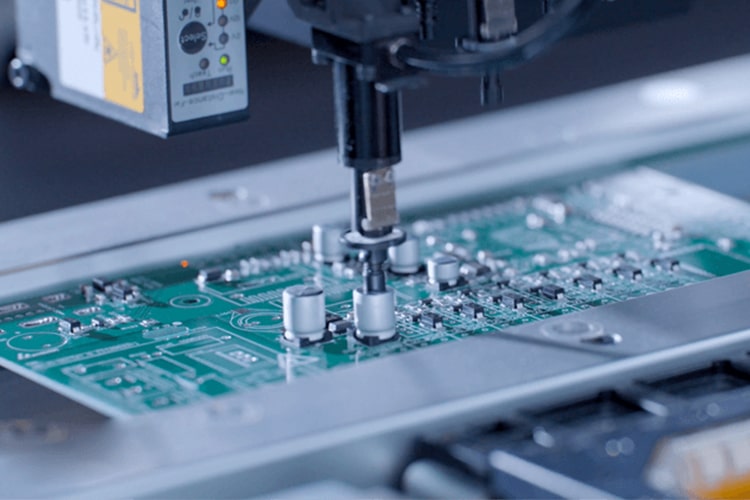

2. Installation: Its function is to accurately install the surface-assembled components to the fixed position of the PCB. The equipment used is a placement machine, which is located behind the screen printing machine in the SMT production line.

3. Reflow soldering: Its function is to melt the solder paste and firmly bond the surface-assembled components to the PCB board. The equipment used is a reflow oven, which is located behind the placement machine of the SMT production line.

4. Inspection: Its function is to check the welding quality and assembly quality of the assembled PCB. The equipment used includes magnifying glass, microscope, online tester (ICT), flying probe tester, automatic optical tester (AOI), X-ray inspection system, functional tester, etc. The position can be configured in the appropriate position of the production line according to the inspection needs.

5. Repair: The function is to repair the PCB board that has detected a fault. Tools used include soldering irons, repair workstations, etc. It can be configured at any position of the production line.

6. Cleaning: Its function is to remove the solder on the assembled PCB and other welding slag that is harmful to the human body. The equipment used is a cleaning machine, and the location can be fixed, online or offline.

These are the specific process flow of SMT patch. Like the pcb manufacturing processing process, it is independent and interlocking. Every link is carefully and carefully taken. Only in this way, manufacturers who pay attention to production details can better provide high-quality products for everyone. .