How to Reduce PCB Fabrication Costs

Today we are going to talk about how to reduce PCB Fabrication Costs.

The goal of every engineer is to achieve the best possible result with the lowest possible cost. Let us discuss the best strategies to reduce the cost of producing PCBs without compromising board quality or functionality.

PCB Size

Larger area, higher price, a printed circuit board should never occupy unnecessary space (unless there are mechanical or electrical reasons to increase the size). Some tips to reduce board size without compromising functionality are:

1.Use appropriate sized components: If a 0402-chip package works well for the project, use it instead of larger packages such as 0603 or 0805. Care must be taken in not to use extremely small components that increase the complexity (and cost) of the printed circuit board assembly. The goal is to reduce the overall production cost, not just the bare board price.

2.Prefer surface mount components: Through hole components tend to be bulkier than surface mount (SMD). Nowadays, most ICs and passive components come in a SMD version, so this is a great alternative to reduce the board size. Besides, SMD assembly is usually cheaper than through hole assembly.

3.Keep components close in PCB Layout: This is good advice (with some exceptions) not only to reduce PCB size, but to improve signal integrity. The shorter the distance between components, the shorter the traces connecting them which results in cleaner signals during device operation.

Layer Count

The same as with board size, a cost-driving factor in PCB fabrication is the number of layers. Because each added layer increases the time the board goes through the different stages in a PCB factory, it has a great impact on the board cost.

For most simple designs, two layers is usually enough. Multilayer boards can be a better option for signal integrity in densely populated designs. The goal here is to achieve a clean layout with the lowest possible number of layers. Careful stack-up planning is recommended before starting a new PCB layout in order to obtain the optimal number of layers.

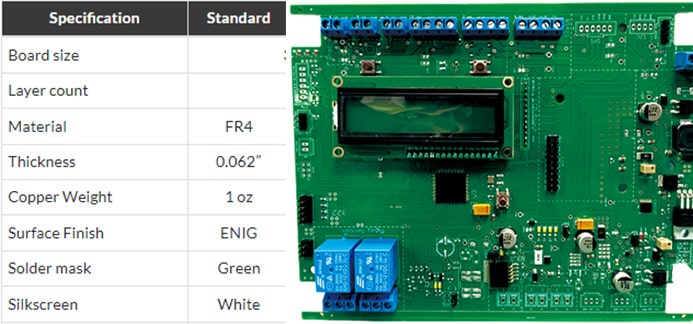

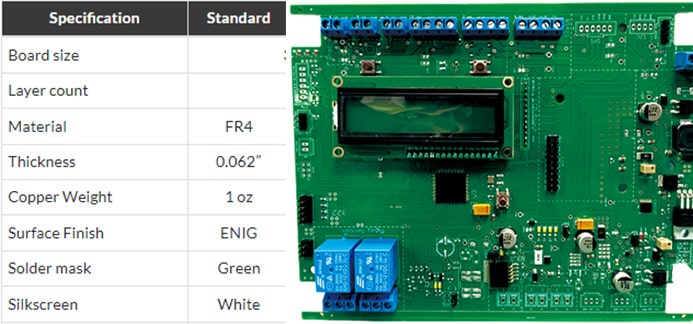

Board Specifications

The same design can be manufactured using multiple combinations of specifications regarding board material, thickness, color, surface finish, and others.

Typically, manufacturers offer a set of specifications that are considered “standard” for which they offer the lowest cost of their price table. Customized or advanced specifications increase the fabrication cost. The vast majority of designs can be made using those so-called standard specifications with very good results in terms of quality.

This table shows the standard specifications in PCBAMake.