What is the reason for baking the PCB board before SMT patch processing?

It is a crucial pre-processing step to bake the PCB board before SMT processing. The main reason is to remove moisture from the board and improve welding reliability.

The importance of baking PCB and components in SMT patch processing

Moisture sensitivity refers to the fact that electronic components, PCBs and other electronic components may absorb too much moisture after long-term storage or exposure to high humidity environments, resulting in irreversible damage during high-temperature reflow soldering. This damage is often called thermal stress cracking during SMD soldering and usually occurs under the solder joints or at the soldering interface.

In SMT patch processing, components on PCBs are bonded to the surface and soldered in a high-temperature furnace. If there is too much absorbed moisture in the PCB and components, when exposed to high temperatures, the moisture will evaporate rapidly and produce steam, which will exert pressure and may cause damage to the solder joints or components. This situation may cause solder joint breakage, component deformation or other irreversible damage, ultimately affecting the reliability and performance of the product.

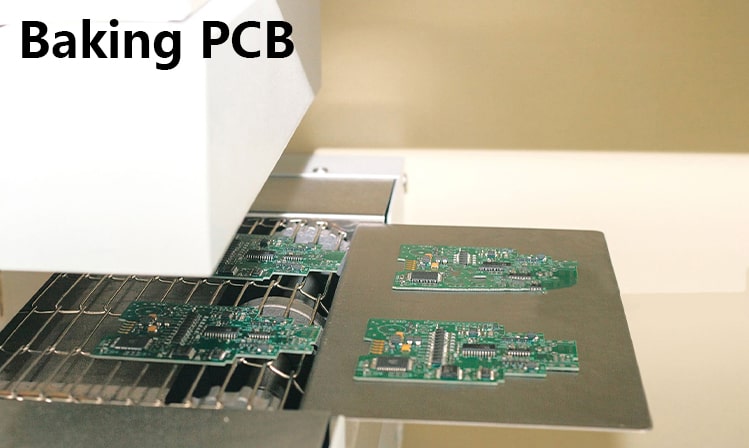

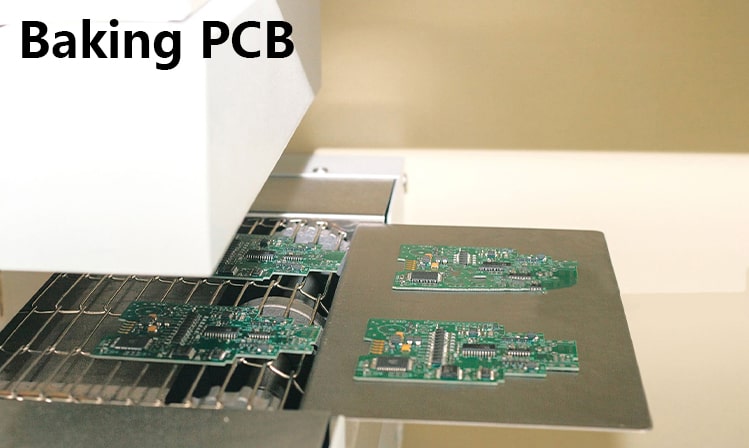

In order to alleviate the problem of moisture sensitivity, PCBs and components often need to undergo a baking process before SMT patch processing. This baking process usually includes the following steps:

1. Drying: PCBs and components that have been stored for a long time are exposed to low temperatures for a period of time to remove absorbed moisture.

2. Baking: PCBs and components are baked at a controlled temperature for a period of time to ensure that any moisture issues are resolved. This process is usually completed using a drying box or oven.

By performing baking, the original state of PCBs and components can be restored, moisture sensitivity can be reduced, and the risk of damage during SMT patch processing can be reduced. This helps ensure the quality and reliability of the final product. Before baking, the moisture sensitivity level of the PCB and components must be understood to determine the required baking conditions and time. This can usually be found in the data sheet or specification book of the component.