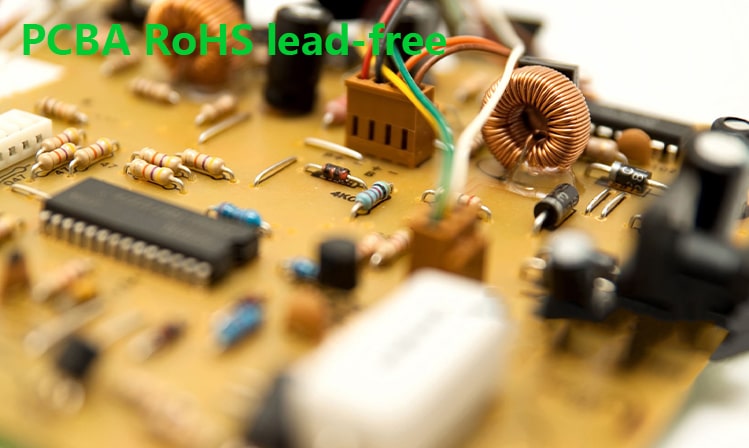

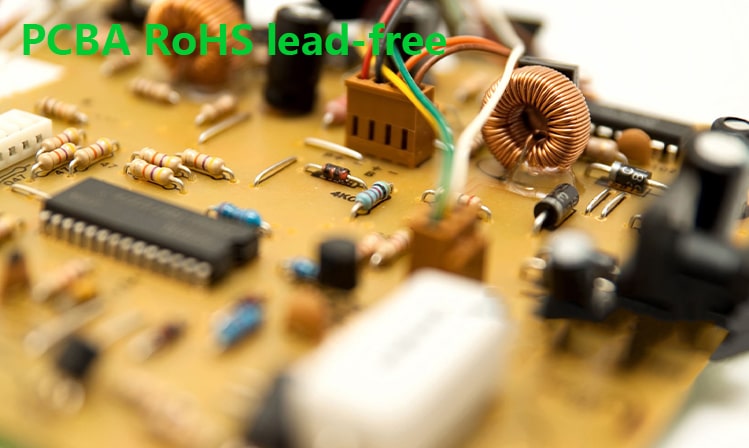

What is RoHS lead-free in PCBA patch processing?

Advantages of RoHS lead-free process in PCBA processing

RoHS (Restriction of Hazardous Substances) is the European Union's environmental regulations for electronic and electrical equipment. The RoHS directive requires that some hazardous substances in electronic products, such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls and polybrominated diphenyl ethers, should be below the specified threshold, the most important of which is lead. Therefore, RoHS lead-free process refers to the use of lead-free process in PCBA processing to meet the requirements of the RoHS directive.

RoHS lead-free in PCBA patch processing:

1. Lead-free soldering: In traditional soldering processes, lead-tin alloys are usually used to connect electronic components to PCBs. RoHS lead-free processes use lead-free soldering materials, such as tin-copper alloys, to replace lead-tin alloys. This can reduce the use of lead and ensure that the soldering connection meets RoHS requirements.

2. Material selection: RoHS lead-free processes require the use of lead-free electronic components and materials, including resistors, capacitors, connectors, ICs, etc. These components should meet the requirements of the RoHS directive and do not contain restricted hazardous substances.

3. Process control: RoHS lead-free process requires strict process control and quality management to ensure the quality and reliability of lead-free soldering. This includes the control of soldering temperature, time and pressure to avoid soldering defects.

Advantages of using RoHS lead-free process for PCBA processing:

Reduce environmental pollution: By reducing the use of hazardous substances, the pollution of electronic products to the environment is reduced.

Improve product sustainability: Products that comply with the RoHS directive are more likely to gain market recognition because they are more environmentally friendly than lead-containing products.

Improve product safety: Lead-free electronic products are safer because lead is harmful to health.

Comply with regulations: The RoHS directive is mandatory for electronic products sold to the European market, so the use of RoHS lead-free process is a necessary condition for compliance with regulations.

RoHS lead-free process has become a standard practice in the electronics manufacturing industry and has been widely adopted worldwide to meet environmental protection and regulatory requirements.

As an experienced EMS PCB provider, we help customers achieve cost savings through smart supply chain strategies and alternative part sourcing.

Backed by our strong components division and global sourcing expertise, we ensure:

Competitive pricing

Certified, traceable components

Full RoHS, REACH, and IPC compliance

Strict in-house quality control at every step

No matter the challenge, we're committed to finding solutions that exceed expectations and drive success.