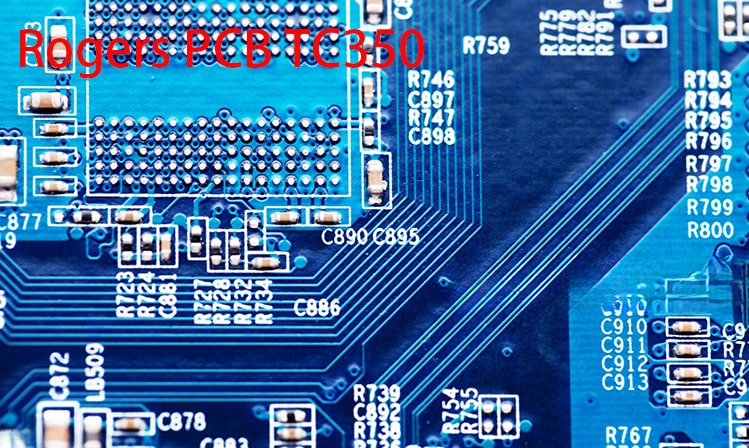

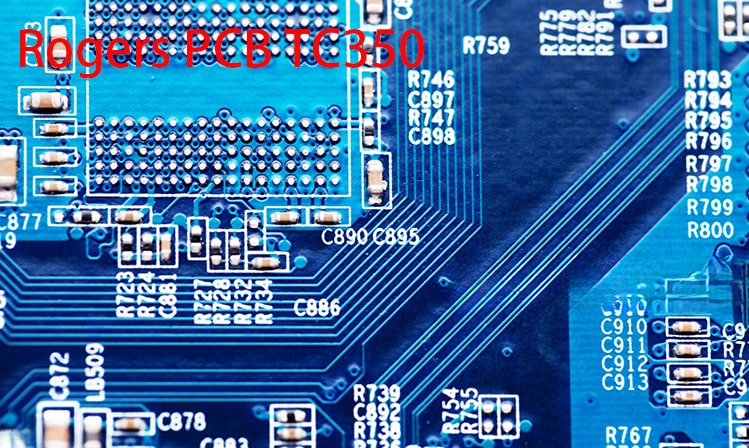

Rogers PCB TC350 and TC600

Rogers TC350 and TC600 high frequency circuit rogers PCB board materials are TC series containing glass fiber reinforced and high thermal conductivity ceramic filled PTFE materials, which can provide better PCB thermal management for applications requiring high power RF signals. The material's low losses, high thermal conductivity, low thermal expansion coefficient and excellent temperature phase stability provide excellent performance and reliability in high-power applications.

Rogers PCB TC series materials are ideal for applications that are sensitive to changes in dielectric constant (Dk) with temperature, including power amplifiers, filters, couplers, combiners, power dividers, etc.

Rogers PCB TC350 and TC600 high frequency circuit boards offer designers a unique combination of low insertion loss and higher thermal conductivity. This allows the product to have excellent reliability in high-power applications and reduces circuit operating temperature, improving equipment reliability. TC600 high dielectric constant has best-in-class thermal conductivity and mechanical properties, which is very suitable for power amplifier designers to better realize the reduction of finished PCB size to reduce the cost of PCB.

There are two substantial differences between Rogers TC350 and TC600:

a. Rogers TC350 dielectric constant Dk: 3.50+/-0.04; loss factor Df: 0.002 (at 10 GHz); thermal expansion XYZ axis coefficient: 7/7/23 (ppm/℃); thermal conductivity: 0.72W/m-K; Fire rating: UL 94V-0

b. Rogers TC600 dielectric constant Dk: 6.15+/-0.15; loss factor Df: 0.002 (at 10 GHz); XYZ axis thermal expansion coefficient: 9/9/35 (ppm/℃); thermal conductivity: 1.0W/mK; Fire rating: UL 94V-0