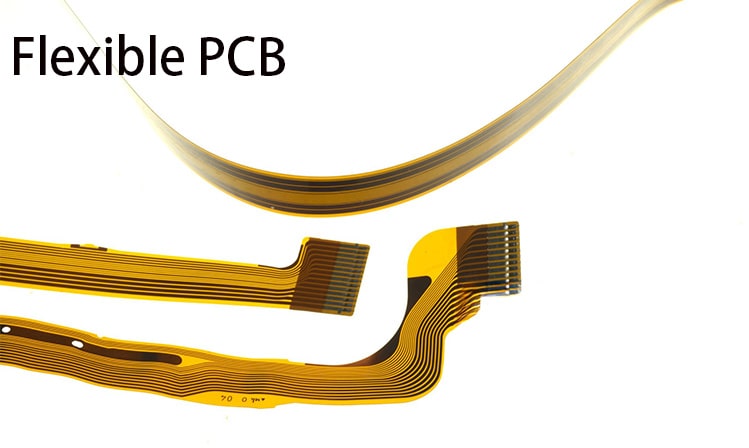

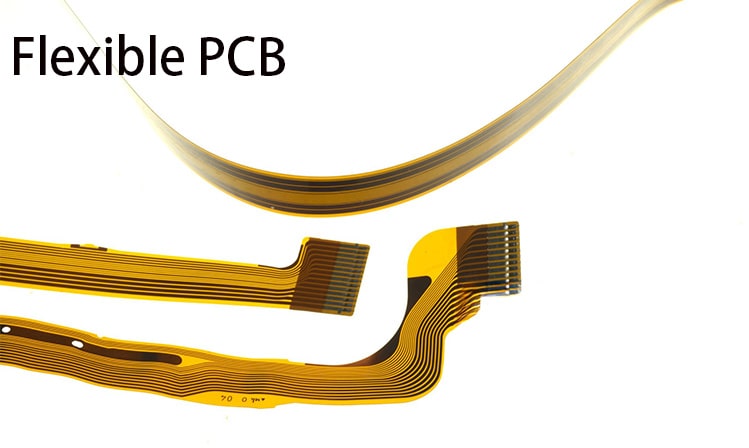

Why are flexible PCBs (flexible circuit boards) more expensive to produce than rigid PCBs (traditional circuit boards)

The main reasons are as follows:

High material cost: The materials used in flexible PCB are more expensive than rigid PCB. For example, flexible substrates usually use materials with high moisture absorption and high temperature resistance such as polyimide (PI), which are relatively expensive. In addition, the conductive layer of flexible PCB is usually made of precious metal materials such as gold and silver, which is more expensive than common conductive materials such as copper.

Complex processing technology: The production and processing technology of flexible PCB is relatively cumbersome and requires multiple processes, including film preparation, film lamination, circuit patterning, photolithography, etching, etc. Each process requires a high degree of precision and professional technology, which increases production costs. In addition, there is a high failure rate in the production process of flexible PCB, because the film material is easily affected by environmental factors during processing, and fine control during the film preparation process is also difficult, which leads to a high scrap rate. .

Large equipment investment: The production of flexible PCB requires special production equipment, including film preparation equipment, film lamination equipment, photolithography equipment, etc. These devices are high-precision, high-stability devices that are expensive, so the investment cost is high. At the same time, due to the high process requirements of flexible PCB, the maintenance and upkeep of equipment also requires higher technical levels and economic investment, which also increases production costs.

High technical requirements: The flexible PCB production process requires a high level of technology. For example, the preparation of conductive materials requires control of their thickness and quality, the film lamination process requires precise temperature and pressure control, and the photolithography process requires high-precision patterning. These requirements require employees to have high technical skills, which increases training and management costs.

The production cost of soft board (PCB) is relatively high, but it has great advantages in some special application scenarios. Although the production process may be affected by a variety of factors, through innovation in manufacturing processes, improvement of worker skills, optimization of production efficiency, etc., production costs can be reduced, thereby improving product competitiveness and market share. PCBAMake is a manufacturer specializing in the production of PCBA. It can provide processing and OEM services. You are welcome to inquire for quotations.