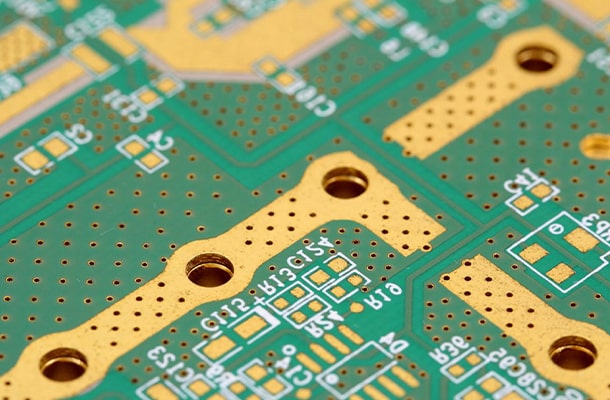

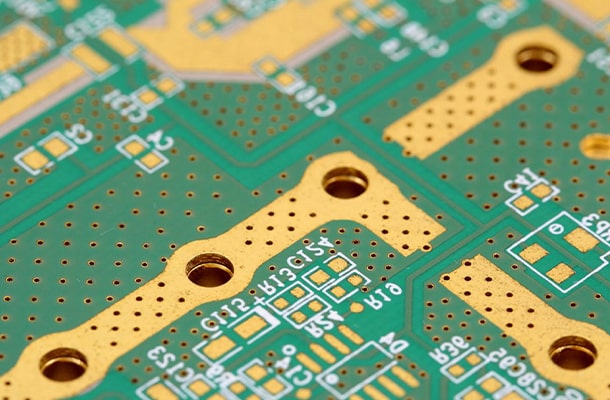

Why do PCB do copper?

PCB copper is filled with solid copper with solid copper without a wiring area on the PCB. The significance of paving copper is to reduce ground impedance and improve anti -interference capacity. It can also reduce the area of the circuit. PCB design paving copper is a very important link of circuit board design.

Why do PCB do copper?

1. EMC has a shielding role in large -scale land or power paving copper, and some special land, such as PGND, play a protective role.

2. PCB process requirements. Generally, in order to ensure the electroplating effect, or the layer pressure does not deform, it is paved with PCB plate layer with less wiring.

3. Signal integrity requirements, a complete return path to high -frequency digital signals, and reducing the wiring of DC networks. Of course, there are also reasons such as heat dissipation, special device installation requirements, and so on.

What is the role of copper when designing PCB?

1. PCB copper paving can improve the conductive performance of the circuit board. Because copper has good conductive performance, the use of copper foil in the process of printing circuit board manufacturing can greatly improve the conductive performance of the circuit board. This can ensure that the connection between each component is more stable and reliable.

2. PCB copper paving can also enhance the mechanical strength and stability of the printing circuit board. Because the copper foil itself has high mechanical strength and stability, it can effectively prevent the printing circuit board from being damaged or deformed during use during use.

3. PCB copper can also protect the circuit board from being influenced by oxidation or corrosion. Because copper foil has good corrosion resistance, coating a layer of copper foil on the surface of the circuit board can effectively protect the circuit board from oxidation or corrosion. This can extend the service life of the circuit board and ensure the stability and reliability of the circuit board during use.

In summary, PCB copper paving is a very important step in the PCB manufacturing process of printing circuit boards.