PCB Manufacturing Overview

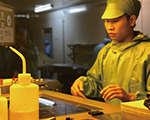

Established in 1996 in Shenzhen, PCBAMake is an engineering-driven PCB manufacturing partner, providing factory-direct production services without intermediaries. .

We focus on end-to-end manufacturing solutions for production-oriented projects, covering PCB fabrication, component sourcing, assembly, testing, and enclosure integration—designed to support medium and small batch orders as well as long-term manufacturing programs.

With over 20 years of proven success in the global EMS (Electronics Manufacturing Services) market, we are trusted by customers worldwide for our high-quality manufacturing, on-time delivery, and professional service.

Our manufacturing capabilities are built to support complex and high-reliability PCB requirements, including HDI PCB and multilayer PCBs (up to 40 layers), thick copper and halogen-free boards. We also specialize in advanced PCB technologies such as rigid-flex PCBs, aluminum PCBs for thermal management, and high-frequency Rogers PCBs for demanding applications.

Committed to long-term partnership, we continuously invest in advanced production equipment, quality systems, and process optimization to ensure stable output, repeatability, and scalability. Our goal is to deliver reliable PCB manufacturing and assembly solutions that help customers successfully manage ongoing projects and compete in demanding electronics markets.