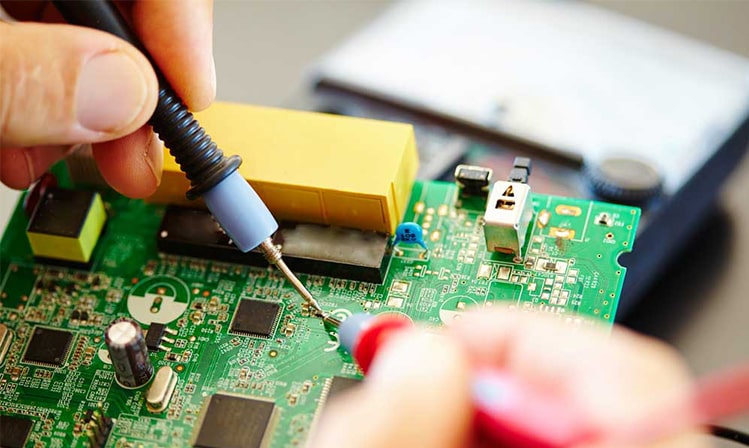

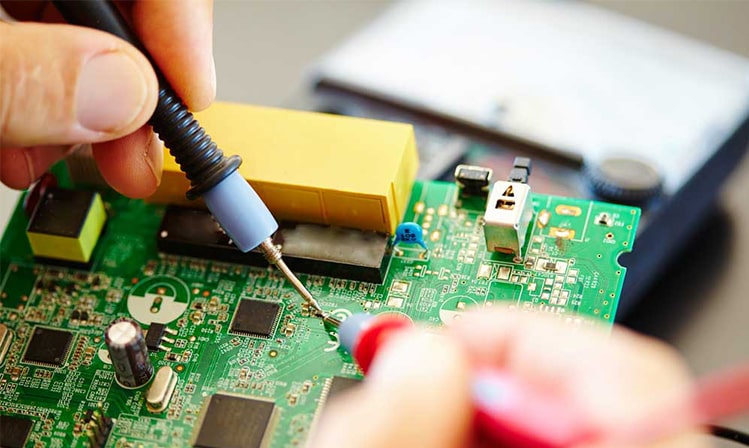

Why does PCBA processing require manual welding?

One stop PCBA manufacturers today will tell you why PCBA processing needs manual welding? The importance of manual welding wiring during PCBA processing. When a small batch of PCBA processing is involved, hand -welded is both fast and economical. When it involves small batch operations, especially through the hole component (soleing line) can be used well with manual assembly. The first PCBA is also benefited from manual welding, because you are regarded as unusual components in small batches.

Automatic optical inspection (X-Ray, 3DAOI, Online AOI) cannot check certain components well, and you need to manually intervene in to verify that there are any welding problems in placing and checking. For surface installation connectors, manual inspection may be required. Sometimes in the process of return, you may encounter small components that need manual cleaning. When you are looking for the maintenance and rework of existing PCBA, the manual process is also effective.

Therefore, these two methods have their own advantages. It is impossible to have a knife -and -cut solution. Therefore, although you will use automated assembly to improve speed, consistency and cost reduction, more and more manual intervention needs to be. You need to cooperate with PCBA processing manufacturers that the manufacturer has necessary SMT processing automation assembly equipment and skilled handmade welding teams; therefore, you can use the correct method according to custom requirements. The next -generation equipment and experienced manpower with the best practice in the industry can play an important role in the production of high -quality PCBAs.

The advantages of PCBA processing manual welding

1. Make up the problem that the machine cannot handle: For some complicated PCB boards or small outlines and irregular components, manual welding can make up for the problem that the machine cannot handle.

2. High accuracy: Hand -welded by professional technicians can ensure the accuracy and quality of the welding joints.

3. Artificial adjustment: Manual welding can correct welding errors by manual adjustment, thereby improving the quality of the PCB board.

4. Wide scope of application: Compared with the machine -based production line, the scope of hand -welding is wider, and it is suitable for processing small batch, high reliability, and high flexibility products.

5. Low cost: Compared with the machine -based production line, the cost of hand -welded is low.

In short, manual welding has great advantages in the field of PCBA processing. Although the manual welding is gradually replaced by automated machinery with the continuous development of automated production, it will continue to exist on some special occasions.

If you want to know more, you can pay attention to PCBAMAKE. If you need to learn more about PCB proofing, Turn Key PCB Assembly,SMT PCB patch, PCBA processing related technical knowledge, please leave a message to get it!