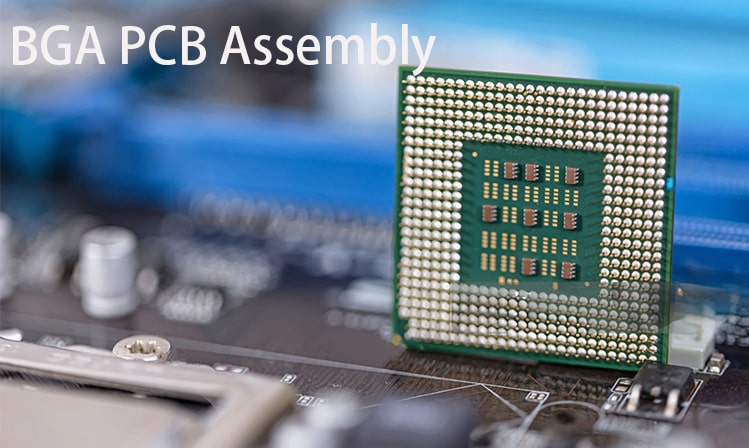

What is BGA

BGA refers to a ball grid array, which is an advanced packaging technology in SMT assembly.

There are many ball-shape bumps on the surface of the tube, which provides a lot of interconnection points to achieve high-density package purposes.

BGA is the result of the development of electronic technology and indicates the significant progress of package technology.

The ball grid array is gaining popularity among SMD ICs that require dense connections. Using the underside of the IC package instead of connections around the edge makes it possible to reduce connection density, hence facilitating PCB layout.

BGA package offers short lead length and ample lead space, it is an ideal solution for high-speed PCB products with high-density circuits.

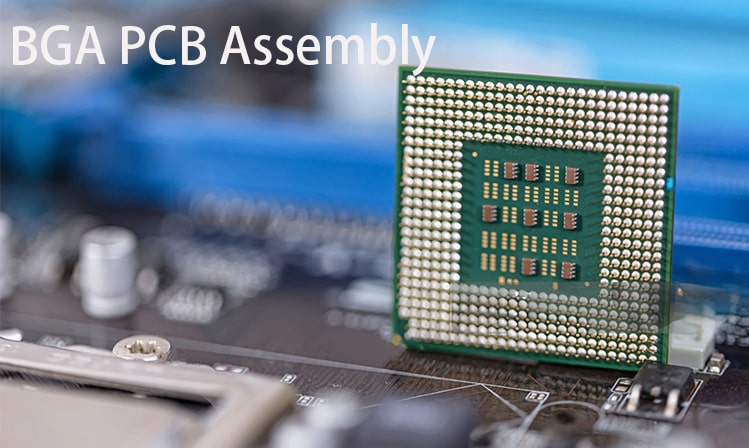

PCBAMake BGA assembly capability

BGA assembly capability?

We are able to handle BGA of 0.25mm pitch with X-ray testing. For BGAs, there are two designs with via on pad and via near pad connected by shorter trace. We need to tent and fill any vias near pad of the BGAs with solder mask to ensure the soldering quality. But for vias on pad, we need to fill via with resin to make sure good soldering quality.

Solder paste printing is the accurate transformation of solder paste from stencil to pad with stencil, so it plays a very important role to decide the BGA quality. Accurate positions of BGA components on printed circuit board is extremely helpful to improve the BGA soldering reliability. PCBAMake normally adjust the stencil thickness to reach the best quality soldering of BGA.

We are very experienced in BGA assembly.

How to ensure the BGA solder quality

Due to the special spherical contact arrangement of the BGA, its solder joints are invisible, and the process specification is difficult. After welding the BGA on top of the PCBA, engineers need to use X-RAY equipment to check and verify the welding quality.

The biggest advantage of X-Ray equipment is that it can inspect all solder joints on the circuit board, also including the invisible ones.

X-Ray can detect solder joint defects in BGA, such as voids, desoldering ( Open circuit), bridging (short circuit), cold soldering, incomplete melting of solder balls, displacement, solder beads; and whether there are air bubbles. insufficient solder volume and other defects, cannot be detected by AOI, therefore, We use X-Ray for BGA once it’s already mounted and welded on top of the circuit board.

PCBAs with BGA mounting require complex management process systems and sophisticated hardware equipment. Only X-RAY testing can guarantee the mounting quality of BGA.

Please subscribe and leave us messages for any questions, we are always there for you!