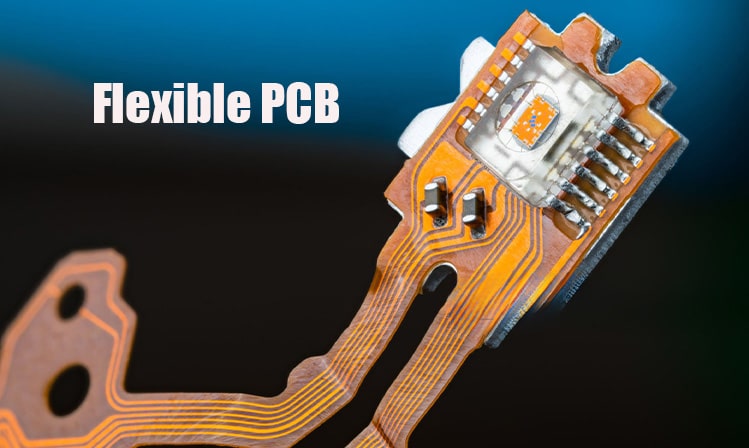

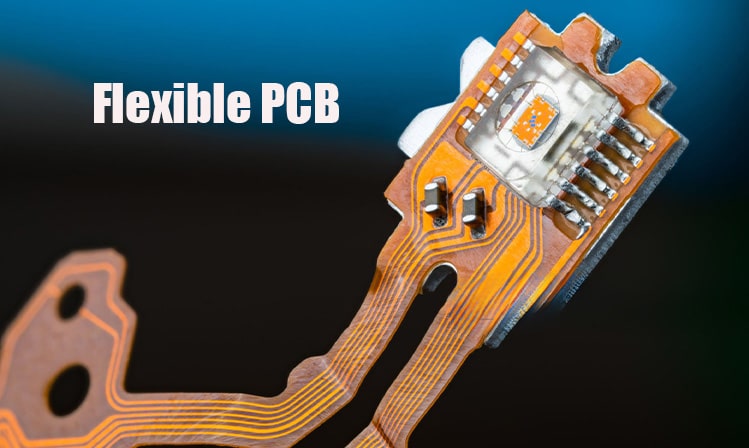

Flexible PCB bending characteristics and its applications

Flexible PCB, or flexible circuit board, is a major innovation in modern electronic products. Unlike traditional PCBs, Flexible PCBs have excellent bendability, which brings greater flexibility and innovation to the design of electronic products.

The main material of soft board PCB is a flexible substrate, such as polyimide (PI) or polyester film (PET), which allows it to be bent in different directions without breaking as easily as traditional PCB. This characteristic makes flex PCB widely used in many fields, especially in electronic products that require high flexibility and compact design.

For example, in wearable devices, the bending characteristics of flexible PCBs are fully utilized. In devices such as smart watches and health monitoring bracelets, the circuit board needs to be tightly attached to the human skin, and the flexibility of the soft PCB makes this design possible. In addition, soft board PCB can also be embedded into clothing to provide users with a more comfortable and convenient experience.

In addition, flexible PCBs also play an important role in medical equipment, aerospace, automotive electronics and other fields. In medical equipment, flexible PCBs can be attached to patients and monitor their physiological data in real time; in the aerospace field, the lightweight and high reliability of flexible PCBs provide strong support for the design and manufacturing of aircraft; in automobiles In electronics, flexible PCBs can be used to manufacture flexible instrument panels, seat heaters and other components to improve the comfort and safety of cars.

In short, the bending characteristics of flexible PCB bring more possibilities and innovations to the design of electronic products. With the continuous development of technology, the application fields of flexible PCB will continue to expand, bringing more convenience and surprises to our lives.