How to prevent the upper plate from the PCB board to prevent the occurrence of the upper plate

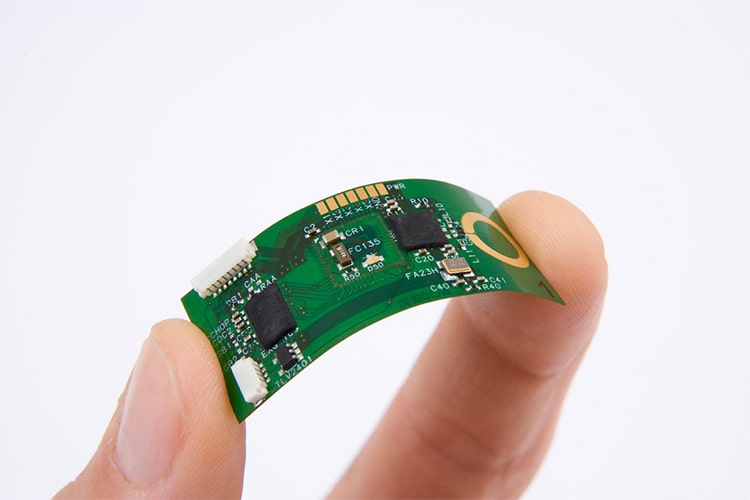

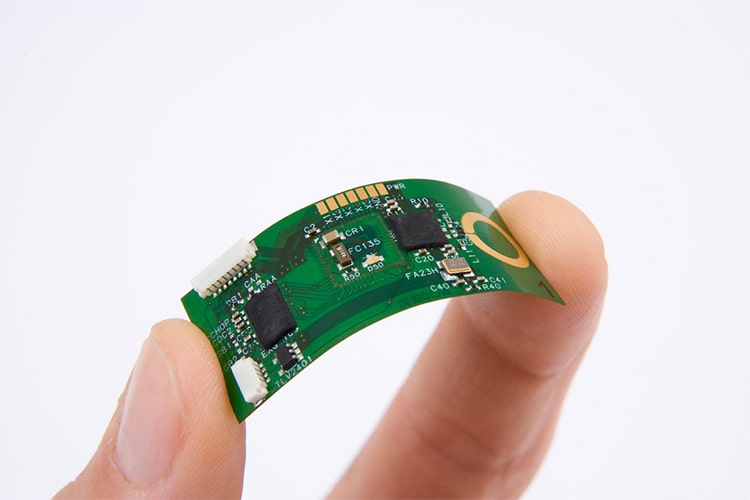

Over -welding furnaces on PCB boards are prone to board bending and plate tilting. Everyone knows, so how to prevent PCB boards from over -welded furnace bending and slab?

1. The effect of lowering temperature on PCB board stress

Since the temperature is the main source of the board's stress, as long as the temperature of the return furnace is reduced or the plate is slowed down in the welding furnace, it can greatly reduce the situation of the plate bending and the front of the plate. However, there may be other side effects, such as short -circuit weld

2. Use high TG board

TG is the temperature of the glass conversion temperature, that is, the material that the material is transformed from the glass state to a rubber state. The lower the TG value, the faster it starts to become soft after entering the welding furnace. It will also become longer, and the deformation of the board will of course, the more serious. The use of higher TG boards can increase its ability to withstand stress deformation, but the price of relatively high material materials is also relatively high.

3. Increase the thickness of the circuit board

In order to achieve a lighter purpose, the thickness of the board is 1.0mm and 0.8mm, and even the thickness of 0.6mm. This thickness must keep the board without deformation after the welding furnace. It is really difficult to be strong. It is recommended that if there is no light requirement, it is best to use the thickness of 1.6mm, which can greatly reduce the risk of plate bending and deformation.

4. Reduce the size of the circuit board and reduce the number of panels

Since most of the welding furnace uses a chain to drive the circuit board to move forward, the larger the size of the circuit board will deform in the back welding furnace because of its own weight, so try to put the long side of the circuit board as the edge of the board on the edge of the board. On the chain of the welding furnace, the depression deformation caused by the weight of the circuit board itself can be reduced. The reduction of the number of panels is also based on this reason. Depression of depression.

5. Use the furnace pallet to treat

If the above methods are difficult to do, the last is to use the furnace pallet to reduce the deformation. The reasons why the cross -furnace tray can reduce the curve is because whether it is hot or cold. After the temperature of the circuit board is lower than that of the TG value, the original size can be maintained.

If a single -layer tray cannot reduce the deformation of the circuit board, you must add another layer of lid to clamp the circuit board with two layers of tray up and down, so as to greatly reduce the problem of the circuit board and the deformation of the welding furnace. However, this tray is very expensive, and it has to be manually set up and recycled the tray.

6. Use Router to replace the split plate of V-CUT

Since V-CUT will destroy the structural strength of the circuit board, try not to use the V-CUT division, or reduce the depth of V-CUT.