Understanding Rogers 5870 PTFE

A High-Performance PCB Material for RF and Microwave Applications

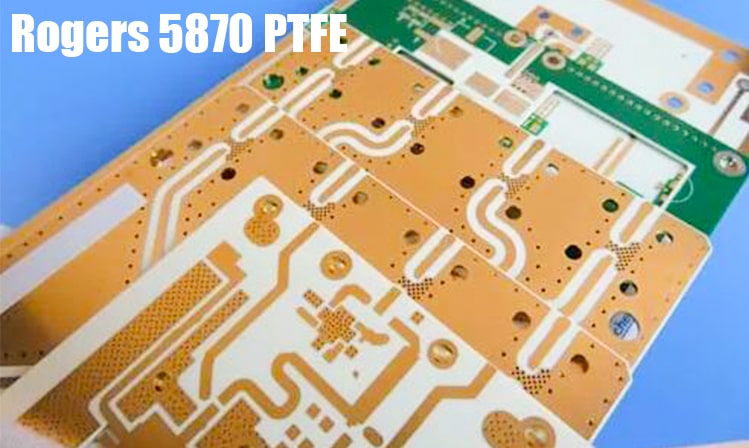

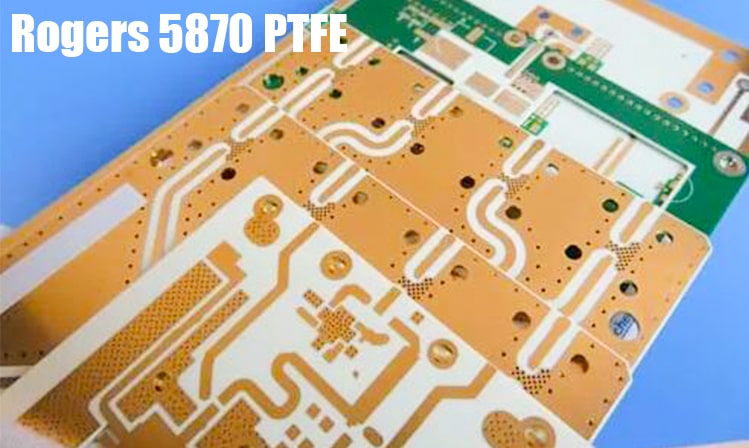

When it comes to high-frequency PCB design, choosing the right material is just as important as the circuit itself. Among many advanced laminates, Rogers 5870 PTFE has become a trusted choice for engineers developing RF, microwave, and antenna applications. But what makes this material so special, and when should you consider using it?

What is Rogers 5870 PTFE?

Rogers RT/duroid® 5870 is a glass microfibre reinforced PTFE composite developed by Rogers Corporation. It is specifically engineered for high-frequency and low-loss PCB applications, where signal integrity and stable performance are critical.

Unlike standard FR4 material, which may cause signal loss and phase distortion at microwave frequencies, Rogers 5870 provides excellent electrical stability, making it ideal for advanced communication systems.

Key Material Properties

Here are the main features that make Rogers 5870 stand out:

Dielectric Constant (Dk): 2.33 ± 0.02

→Extremely low and stable across a wide frequency range.

Dissipation Factor (Df): 0.0012 at 10 GHz

→Ensures minimal signal loss and excellent transmission efficiency.

Water Absorption: < 0.02%

→High moisture resistance, ideal for humid or outdoor environments.

Thermal Stability:

→Performs reliably over a wide temperature range without dimensional changes.

Mechanical Strength:

→Reinforced with glass microfibre for dimensional stability during PCB fabrication.

Why Choose Rogers 5870 Over FR4

Feature | FR4 | Rogers 5870 PTFE |

Dielectric Constant

| ~4.2

| 2.33

|

Signal Loss (at GHz range)

| High

| Very Low

|

Frequency Stability

| Limited

| Excellent

|

Moisture Resistance

| Moderate

| Excellent

|

Ideal Use

| General electronics

| RF, microwave, antennas

|

In short, if your design involves high-frequency transmission lines, antenna systems, or radar sensors, Rogers 5870 delivers significantly better electrical performance than standard FR4.

Typical Applications

Rogers 5870 PTFE is commonly used in:

Satellite communication systems

GPS antennas and radar modules

Microwave amplifiers and filters

RF sensors and transmitters

Aerospace and defense systems

These applications benefit from its low signal loss and consistent dielectric properties, even in harsh or high-frequency environments.

Manufacturing Considerations

Processing Rogers 5870 requires precision and experience. Compared with FR4, PTFE-based materials are softer and more flexible, which means:

Specialized drilling and plasma etching are needed for via preparation.

Controlled lamination temperature and pressure are required.

Surface treatment is essential to improve copper adhesion.

At PCBAmake, our production team is experienced with Rogers series laminates and mixed-material stack-ups (such as FR4 + PTFE hybrid designs). This allows us to deliver high-frequency PCBs with stable impedance control and excellent signal performance.

Summary

Rogers 5870 PTFE is a premium choice for high-frequency PCB designs where performance and reliability are critical. Its ultra-low dielectric loss, stable electrical properties, and moisture resistance make it ideal for RF, microwave, and antenna applications.

If your next project involves high-speed communication or signal-sensitive circuits, our engineering team can help you select the right Rogers material, optimize your stack-up, and ensure manufacturability.

PCBAmake — Your Trusted Partner for High-Frequency PCB Manufacturing

We provide complete PCB fabrication and assembly services, supporting Rogers, Taconic, Arlon, and other advanced laminates.Contact us to discuss your RF or microwave PCB requirements today.

Quote online:Orders@pcbamake.com