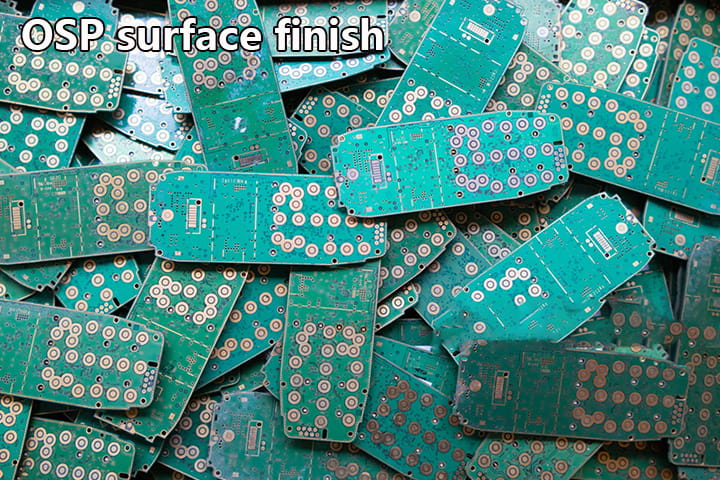

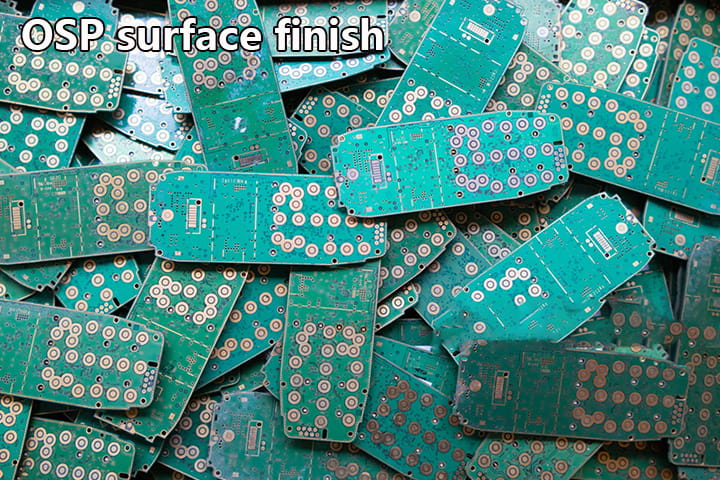

OSP Surface Finish in PCBA: Cost Advantages and Manufacturing Limitations

OSP (Organic Solderability Preservative) is widely used in cost-driven PCBA projects.

While it offers clear pricing advantages, OSP also introduces manufacturing constraints that must be carefully managed.

What Is OSP Surface Finish?

OSP is an organic coating applied to copper to prevent oxidation.

Unlike metallic finishes, OSP Is extremely thin,Relies heavily on process control and timing

Advantages of OSP in PCBA

1. Lowest Surface Finish Cost

OSP is typically the most economical option, making it attractive for:

Consumer electronics

Large-volume, cost-sensitive products

2. Good Initial Solderability

For first-pass SMT:

OSP provides good wetting

Flat copper pads support standard components

Key Limitations in PCBA Manufacturing

1. Poor Multi-Reflow Performance

OSP degrades after:

Multiple reflow cycles

Extended thermal exposure

This limits its use in complex assemblies.

2. Short Shelf Life

OSP boards require:

Controlled storage

Short time between PCB fabrication and assembly

Logistics delays significantly increase risk.

3. Narrow Process Window

OSP demands:

Precise reflow control

Clean handling

It leaves little margin for manufacturing variation.

Best Application Scenarios for OSP

Low-density PCBA

Single-pass reflow

Short production cycles

Highly cost-sensitive projects

👉 For higher density or reliability requirements, ENIG or immersion silver are usually better choices.

Related reading:

ENIG Surface Finish in PCBA: When Is ENIG the Best Choice?

Immersion Silver Surface Finish for PCBA Applications

OSP is not a “low-quality” choice—but it is a high-discipline choice.

When conditions are right, it delivers excellent cost efficiency.

When conditions are not controlled, it introduces significant manufacturing risk.