Why Choose an Offshore PCB Manufacturing Partner?

Key Advantages for Your Electronics ProjectsWhen it comes to PCB production, choosing the right manufacturing partner directly affects cost, speed, and product quality. For many companies in Europe and North America, working with an offshore PCB manufacturer has become a strategic choice. But why do so many brands, OEMs, and electronics companies go this route? Here are the main advantages.

Cost-Effective Production

Offshore PCB factories—especially in Asia—offer significant savings in labor, materials, and equipment costs. This makes it possible to:

Reduce total project costStay competitive in pricingFree up budget for R&D or marketingEven with shipping fees, overall spending is often much lower than local manufacturing.

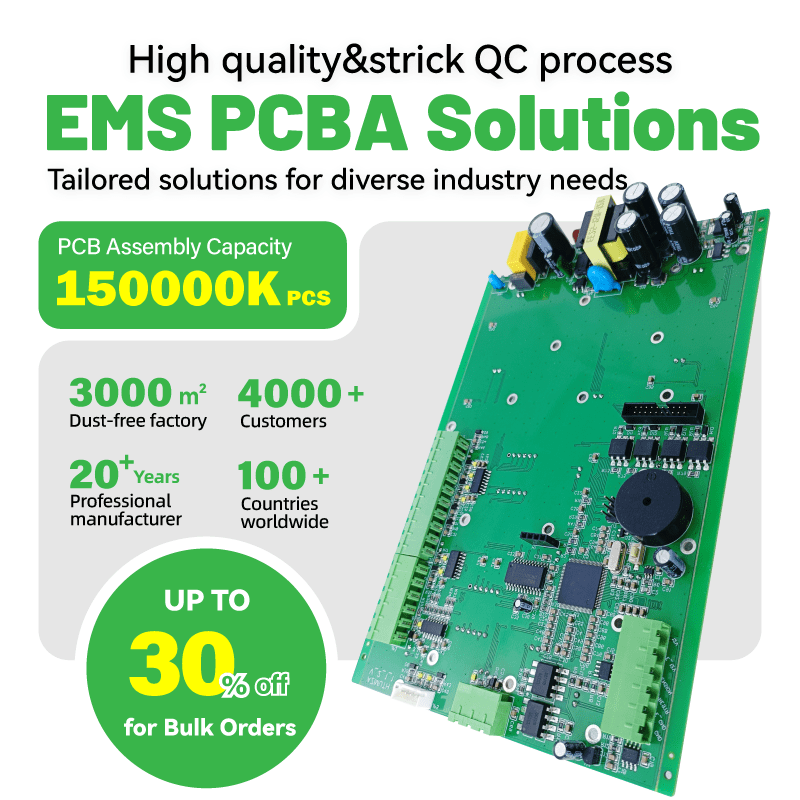

Complete Manufacturing CapabilitiesA reliable offshore PCB manufacturer usually offers one-stop services, including:PCB fabrication (single, double, multilayer, HDI, rigid-flex)SMT assembly and THT assemblyComponent sourcingIC programming and testingFunctional inspection and packagingThis minimizes outsourcing risk and shortens your production cycle.Fast Prototyping and Mass ProductionWith dedicated production lines and flexible capacity, offshore manufacturers can handle different order sizes:Quick prototypes for engineering verificationSmall-to-medium runs for pilot buildsLarge-volume production for market launchLead times are often faster due to optimized processes and 24-hour factory operations.Access to Global Component Supply ChainsEstablished PCB manufacturers have long-term partnerships with component distributors and original brands. They can:Source alternative parts quicklyAvoid shortages or long lead timesOffer full or partial turnkey optionsThis helps your team avoid sourcing delays and procurement headaches.Strong Quality ManagementMany offshore PCB factories follow international standards such as:ISO 9001IATF 16949UL certificationRoHS and REACH complianceWith advanced inspection systems (AOI, X-ray, ICT, FCT), quality is controlled at every step—from incoming materials to final testing.Flexible Customization & Engineering SupportOffshore manufacturers are used to working with clients from different industries, including telecom, medical, industrial control, automotive, and consumer electronics. They offer:DFM (Design for Manufacturability) suggestionsMaterial and stack-up selectionCost optimizationEngineering file reviewThis reduces errors and ensures smooth production before mass manufacturing.Scalability for Long-Term ProjectsAs your order grows, offshore factories can easily increase capacity without affecting delivery schedules or quality standards. You don’t need to switch suppliers every time order volume changes.Secure IP ProtectionToday’s manufacturers understand that IP protection is critical for global customers. With NDAs, controlled access systems, and closed production lines, your designs and firmware remain confidential.

Partnering with an offshore PCB manufacturer isn’t just about cost savings—it’s about flexibility, capacity, and global-standard quality. With the right supplier, your production becomes more scalable, efficient, and competitive.

If you’re looking for a trusted PCB manufacturing and assembly partner with one-stop services, we’re here to support your next project.

If you need help, please contact us! Orders@pcbamake.com

Need a PCB or PCBA quote? Quote now