How to quickly repair PCBA after processing failure

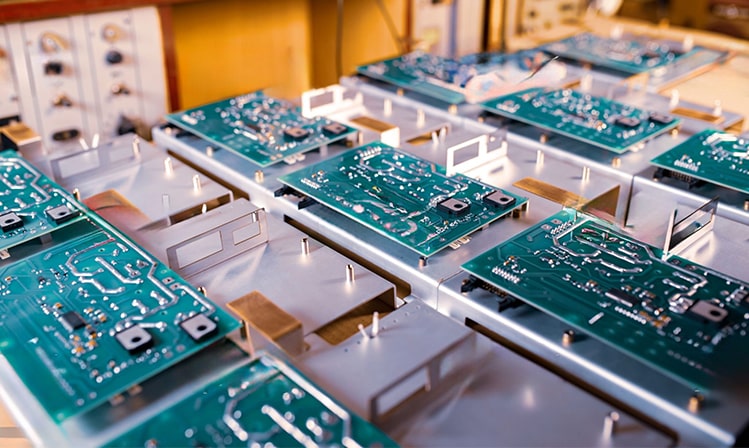

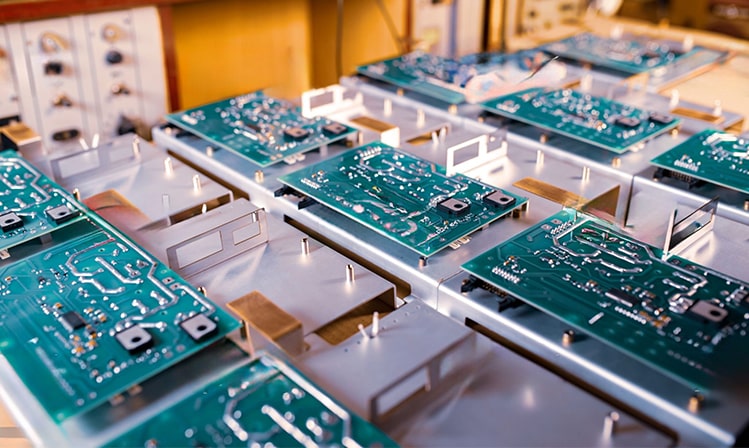

PCBA refers to the installation of electronic components installed on the PCB to form an electronic product. PCBA processing refers to a series of processes such as welding, testing, and assembly of PCB boards and components to make it a complete circuit system. PCBA processing is an important part of the electronic PCB manufacturing industry, and it is also a key factor affecting product quality and performance.

However, during the PCBA processing process, some faults may occur due to various reasons, resulting in the failure of the circuit board to work normally or decreased. These faults may include:

-The welding: Due to the inappropriate parameters such as the welding temperature, time, pressure, welds, and welding agents, or irregular operations, welded welding, leakage welding, short circuit, tin bridge, tin beads, etc. And reliability.

-Capor device damage: Due to the quality problems of the component itself, or in the process of transportation, storage, assembly, testing, etc., are affected by factors such as static electricity, mechanical impact, overheating, overvoltage and other factors. Function and stability.-Design defects: Due to the lack of levels or experience of the designer, or the error of the design software, the circuit board's wiring is unreasonable, the impedance is not matched, the signal interference, and poor heat dissipation affects the performance and efficiency of the circuit.

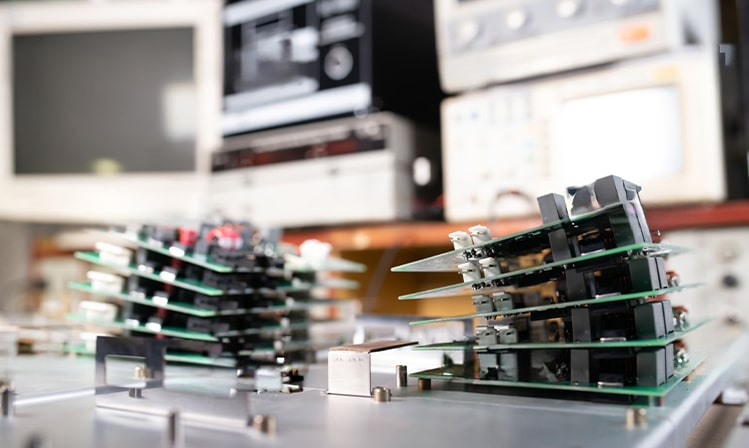

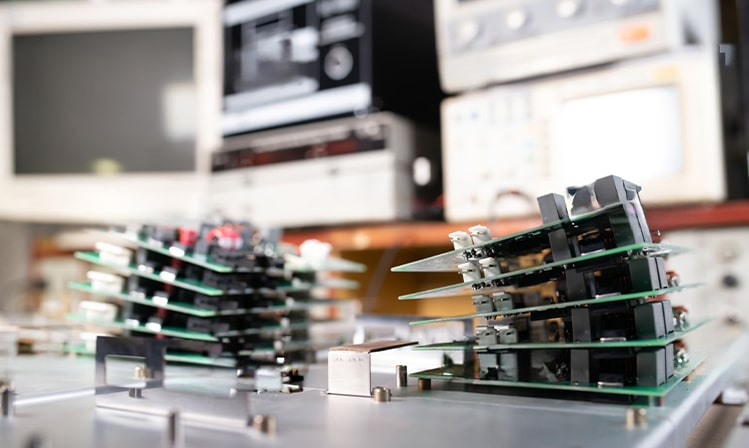

So, how to quickly repair articles that fail after PCBA processing? Here are some commonly used methods:

-Base: Through tools such as the naked eye or amplifying mirror, observe whether there are obvious abnormal phenomena on the surface of the PCBA, such as welding joint cracks, discoloration, falling off, etc., whether the components are damaged, deformed, burnt, etc. Essence Observation methods can quickly locate some obvious fault points, but other methods are required for some hidden or tiny fault points.

A measurement method: Make the voltage, current, impedance, waveforms and other parameters of each node on the PCBA through the instruments such as universal meters, oscilloscope, and compare whether there are abnormal values to determine whether it is abnormal. The measurement method can accurately detect some fault points in electrical performance, but requires certain professional knowledge and experience.The comparison method: By comparing the normal PCBA of the same batch or the same model with the fault PCBA, the difference between the two is found to judge the cause of the fault. The contrast method can effectively exclude some accidental factors or individual phenomena, but requires the same or similar reference samples.Entertainment: By analyzing the functional relationship and signal flow between each module or component on the PCBA, the possible fault range and reasons are inferred according to the fault phenomenon. Analysis method can systematically solve some failure problems caused by complicated or multiple reasons, but require strong logical thinking and innovative ability.

The above four methods are not in isolation, but are combined with each other and verified each other to achieve the purpose of rapid maintenance of PCBA processing. During the maintenance process, you need to pay attention to the following points:

-Co follow safety norms to prevent accidents such as electric shock, burns, scratches.

-In the use of suitable tools and instruments to prevent secondary damage to PCBA or components.

-The record the maintenance process and results, facilitate subsequent analysis and improvement.

-Stchang or repair the faulty PCBA or component to restore the normal working state.