Standards and requirements for medical circuit boards

With the advancement of science and technology, more and more medical research is born, and corresponding medical equipment appears. More medical circuit boards are used in places related to medical equipment. Medical circuit boards are a special circuit board. Its quality and reliability are critical to patients as this relates to safety issues.

So what requirements and standards do medical circuit boards need to comply with during production?

Standards and requirements for medical circuit boards

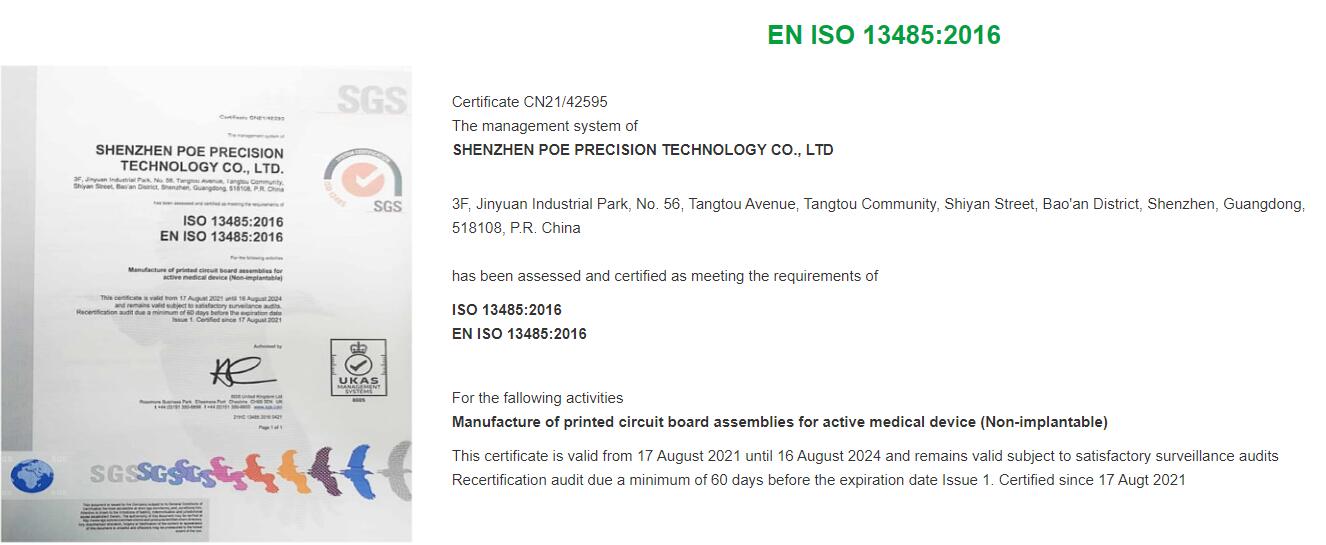

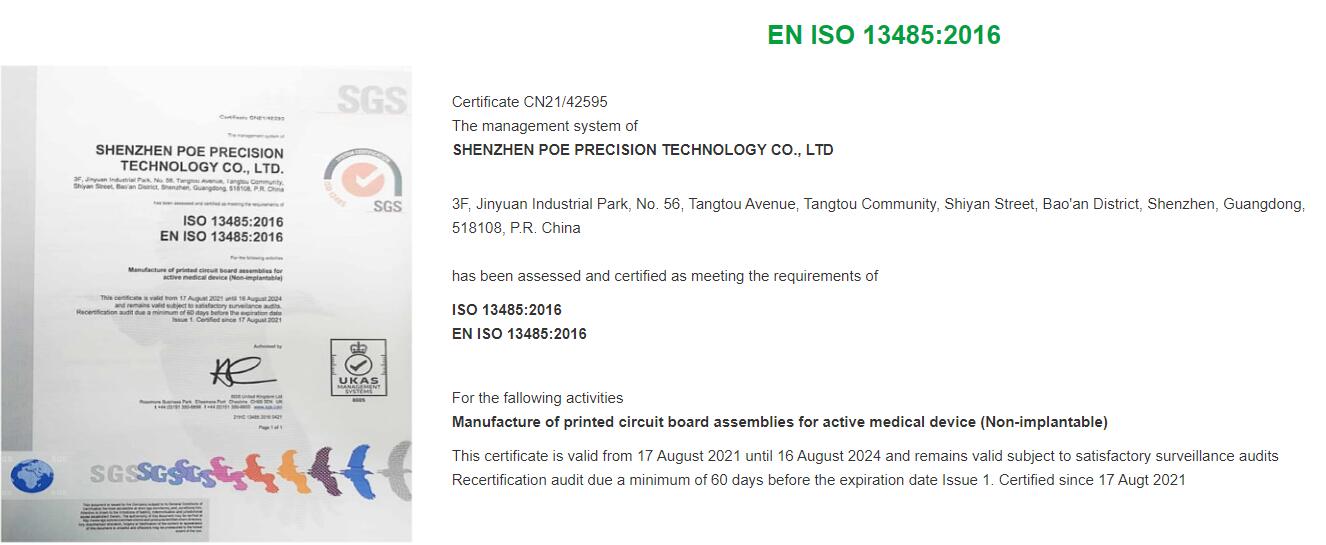

1.ISO13485 standard

The production of medical circuit boards must comply with the requirements of the ISO13485 quality management system, which is the international standard for medical device production. The ISO13485 standard is consistent with the ISO 9000 series and also specifies the quality and reliability of medical products.

All aspects of medical electronic pcba OEM and material procurement need to follow strict access qualifications. This is a very important requirement for PCBA processing plants. ISO13485 certification requires manufacturers to record all manufacturing process data in order to control the production process according to standards. It also specifies the details of risk management and control processes. Manufacturers need to have an audit system to track the SMT processing plant's own workmanship throughout the process.

With these standards and supervision, PCBA manufacturers are fully capable of achieving stable quality of this type of products and have the necessary systems and processes in place. Therefore, only SMT patch processing manufacturers that have obtained ISO13485 qualification certification can perform corresponding product production.

2.IPC-A-610 standard

The IPC-A-610 standard was developed to ensure the quality of electrical and electronic components. It includes appearance and quality standards, welding and assembly requirements, and electrical performance parameters. This standard requires that the welding and assembly of medical circuit boards must meet certain requirements to ensure the long-term reliability and stability of the board.

3.IPC-6012D standard

The IPC-6012D standard is a rigid printed board quality and reliability standard that sets forth requirements for the design, manufacturing and verification of medical circuit boards. Medical circuit boards must be designed and manufactured in accordance with the relevant requirements of IPC-6012D to ensure their quality and reliability.

In short, the IPC grade and production qualification requirements of medical circuit boards are important indicators to ensure product quality and reliability. Understanding and complying with these requirements and standards can improve the quality and reliability of medical circuit boards and protect the safety and health of patients.