The secret of PCBA coating

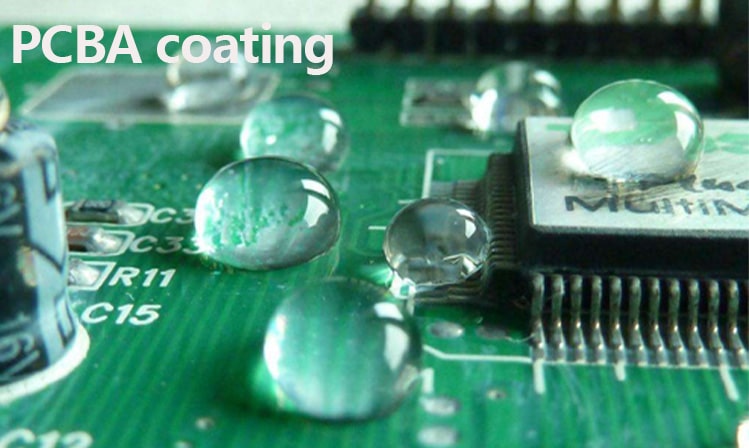

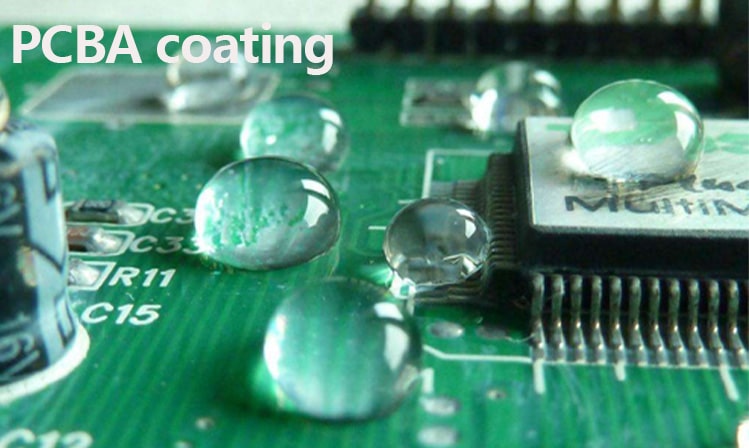

Conformal coatings are specialized polymer film-forming products that protect circuit boards, components and other electronic devices from adverse environmental conditions. The film conforms perfectly to the shape of the PCBA and can be applied to the part and conform to the topography. Each coating has unique chemistry and can be customized for specific protective properties. These coatings are not limited by PCBA structure or other environmental factors, and they provide higher dielectric resistance, thereby protecting the board from corrosive environments, humidity, and contaminants such as dirt and dust.

Coating thickness standard requirements:

The normal coating thickness for most circuit board products is 25 to 127 microns, with some products having lower coating thicknesses. Circuit boards must provide maximum protection using the thinnest coating materials available to minimize heat trapping.

The thicker the Baoxing coating, the better the effect. Many users are misled into thinking that thicker is better. Not necessarily, conformal coatings can be made of acrylic, silicone or polyurethane resins, as well as other more application-specific compounds (such as epoxy resins)

Different types of coatings have different thickness requirements, and various industries have different requirements for Baoxing coating thickness.

Because each type of product has different requirements for coating thickness during use, each product also has different coating thickness when used in different environments and needs.

For example, ordinary electronic products do not have particularly high coating requirements. There is no special thickness requirement during coating. Generally, a thickness of 20-30 microns is enough. If there are special requirements, multiple coatings can be used. The second coating can be carried out after the Baoxing coating on the board is completely solidified.

Industrial products and military products have relatively high performance requirements for Baoxing coatings. The thickness of the coating is about 30-50 microns. At the same time, coatings with relatively better performance are selected to better protect circuit boards.

How to apply conformal coating:

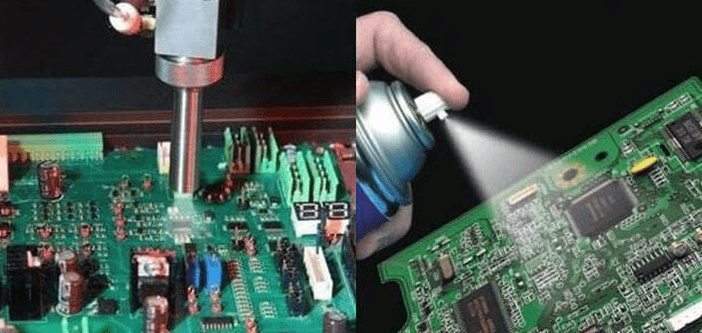

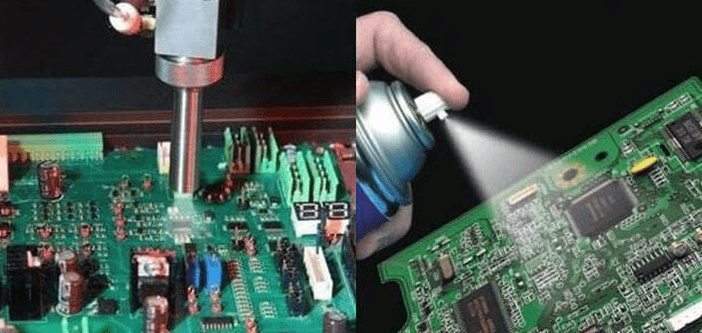

Manual spraying: PCB Conformal coating can be sprayed using an aerosol can or hand-held spray gun. It is generally suitable for use without fixed equipment. It is usually used for small batch production. For example, in the prototype production line, which is used to produce prototypes in the design and development stage, this method is generally used.

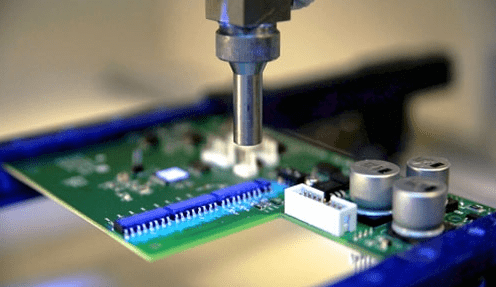

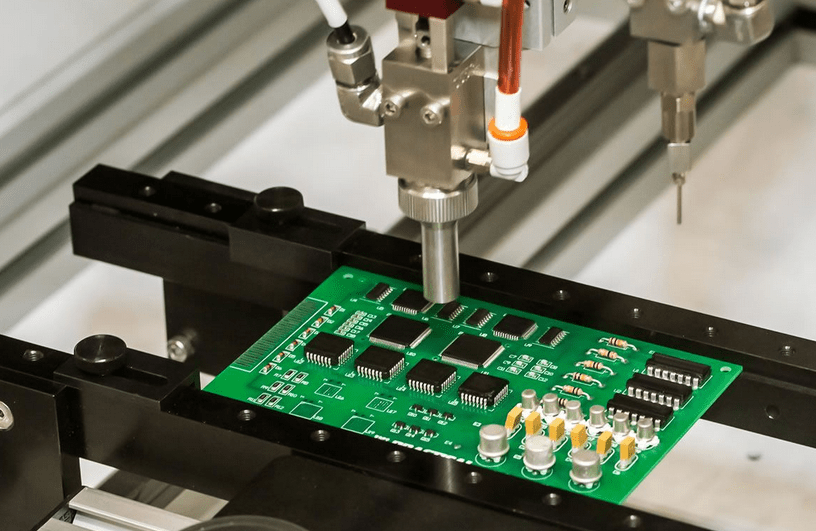

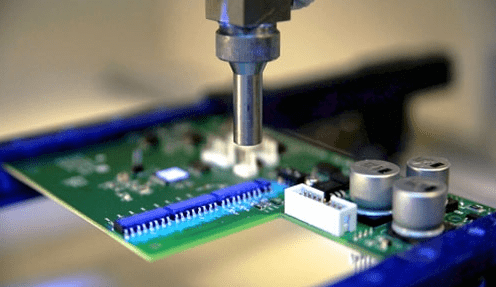

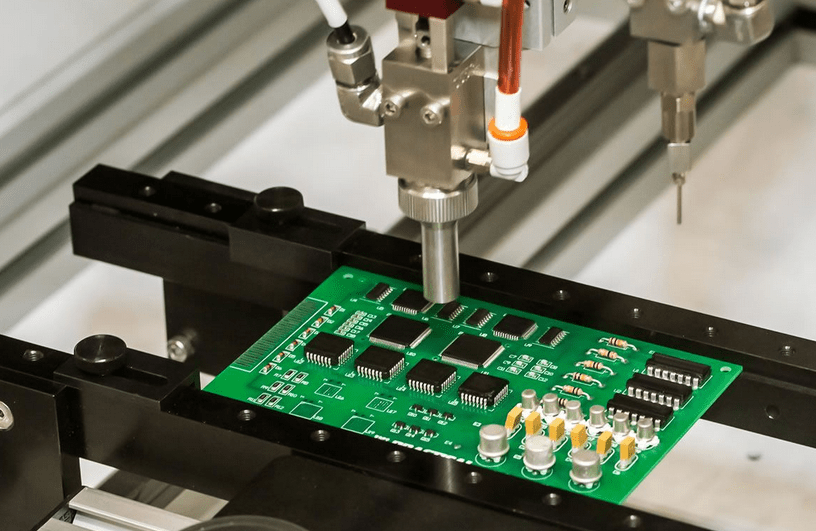

Automatic spraying: This is a programmed spraying system that moves circuit boards on a conveyor belt. When the circuit board moves to a specific position, a spray head will perform the coating operation.

Selective coating: This is also an automatic conformal coating process that can apply paint to specific areas on the circuit board. It is more suitable for mass production and is somewhat similar to selective wave soldering.

Spraying steps of Baoxing coating:

Step 1: Clean the board surface and keep it free of oil and dust (mainly the flux component in the residual solder during the welding process, because it is mainly acidic substances that will affect the durability of the components and the coating and Adhesion to the board surface

Step 2: Dry. Dry the cleaned detergent and water to ensure the dryness of the board surface.

Step 3: According to the data provided by the manufacturer of Baoxing Coating, prepare the coating with appropriate viscosity.

Step 4: Spray.

Step 5: After spraying the board surface, put it into the oven for baking, and set the curve baking temperature according to the data provided by the paint manufacturer. If the paint is self-drying, if it is a vertical oven, it is recommended to let it sit outside for 3-5 minutes and then bake it in an oven not exceeding 80 degrees for 5-10 minutes.

Step 6: Inspect the board after collecting it. Take the board out of the baking oven and check whether there are any leaking bubbles. If the paint film on the board is uniform, complete and free of bubbles, it is qualified.

Conformal coatings are very necessary for PCBs and PCBAs that must work in harsh environments. It is important to note that we do not confuse conformal coating with PCB surface treatment. Conformal coating is different from PCB surface treatment because the coating is applied after the circuit board is assembled, that is, the conformal coating is applied after SMT production; while PCB surface treatment is a part of the PCB manufacturing process part. Both processes protect circuit boards, but do so in different ways.