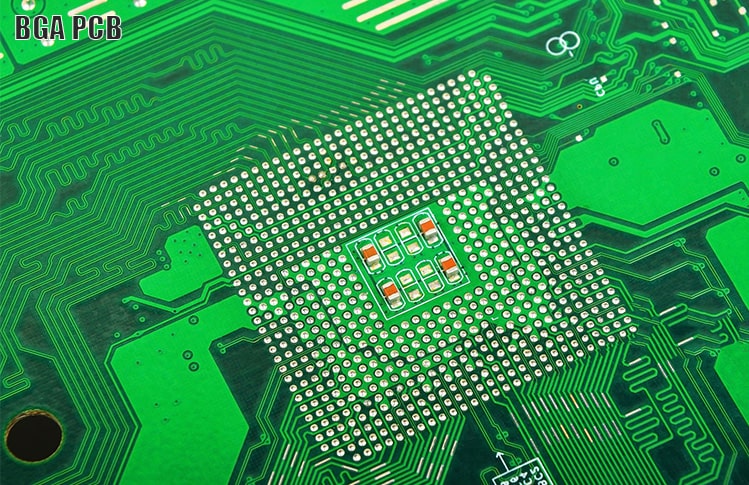

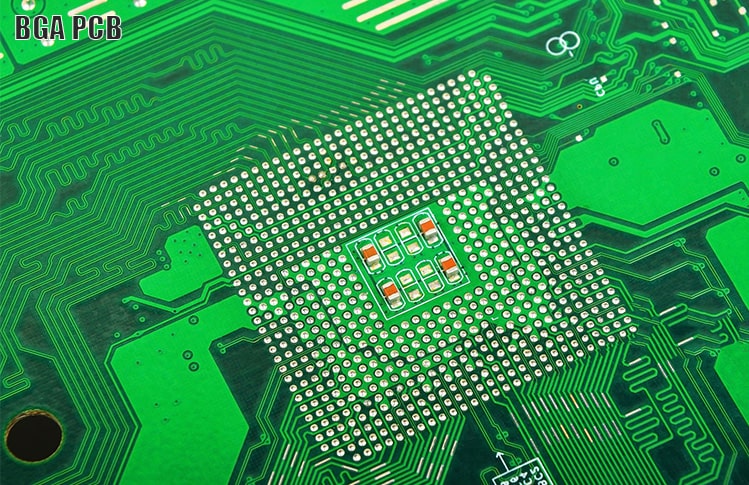

BGA PCB Assembly

BGA PCB assembly refers to the process of mounting Ball Grid Array components onto a printed circuit board using solder balls instead of traditional leads or pins.

Unlike through-hole or leaded packages, BGA components are soldered directly to surface pads during reflow soldering, forming strong electrical and mechanical connections.

Why BGA PCB Assembly Is Widely Used

BGA PCB assembly offers several advantages over conventional PCB assembly methods:

High-Density Interconnection

BGA packages allow hundreds or thousands of I/O connections in a compact footprint, making them ideal for high-density PCB assembly.

Improved Electrical Performance

Shorter signal paths reduce impedance, signal loss, and EMI, which is essential for high-speed and high-frequency applications.

Better Thermal Management

Heat is efficiently transferred through the solder balls into the PCB, improving reliability for power-hungry components.

BGA PCB Assembly vs. PGA and LGA

Understanding packaging differences helps select the right assembly solution.

Package Type Assembly Method Typical Use

BGA PCB Assembly Solder balls + reflow High-speed, compact electronics

PGA PCB Assembly Pins + through-hole Legacy or low-density designs

LGA PCB Assembly Flat pads + socket or solder CPUs, replaceable ICs

Compared to PGA and LGA, BGA PCB assembly delivers higher reliability and better signal integrity but requires more advanced manufacturing capabilities.

Key Challenges in BGA PCB Assembly

Despite its benefits, BGA PCB assembly presents unique technical challenges:

Hidden solder joints that cannot be visually inspected

Tight control required for solder paste printing

Precise reflow temperature profiling

Complex BGA rework and repair processes

To overcome these issues, professional manufacturers use:

SPI (Solder Paste Inspection)

AOI + X-ray inspection (AXI)

IPC-standard-controlled assembly processes

Best Practices for Reliable BGA PCB Assembly

To ensure high-quality BGA PCB assembly, experienced suppliers follow these best practices:

Use optimized stencil design for BGA pads

Control moisture sensitivity levels (MSL) of BGA components

Apply nitrogen reflow for complex BGA soldering

Perform X-ray inspection on every BGA board

These steps significantly reduce voids, head-in-pillow defects, and cold solder joints.

Applications of BGA PCB Assembly

BGA PCB assembly is commonly used in:Industrial automation and control boards,Automotive electronics and ADAS systems,Medical devices,Telecommunications equipment,High-end consumer electronics.A reliable partner ensures consistent quality from prototype to volume production.

Why Choose PCBAMake for BGA PCB Assembly?

At PCBAMake, we specialize in advanced BGA PCB assembly for high-density and high-reliability applications. Our production lines are equipped with state-of-the-art SPI (Solder Paste Inspection), AOI (Automated Optical Inspection), and X-ray inspection systems, ensuring every BGA solder joint meets strict quality standards.

From fine-pitch BGA to complex multilayer PCBs, our experienced engineering team and IPC-compliant processes enable us to deliver consistent quality from prototype to volume production. Whether your project requires precision, reliability, or advanced PCB manufacturing capabilities, PCBAMake is fully equipped to support your most demanding PCB and PCBA requirements.