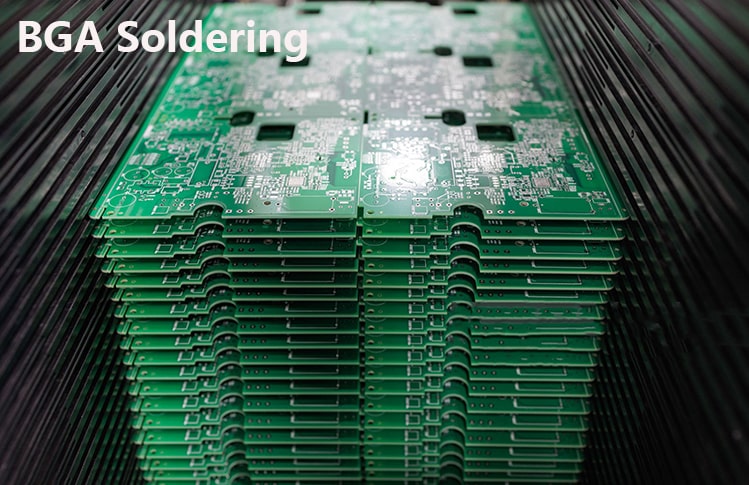

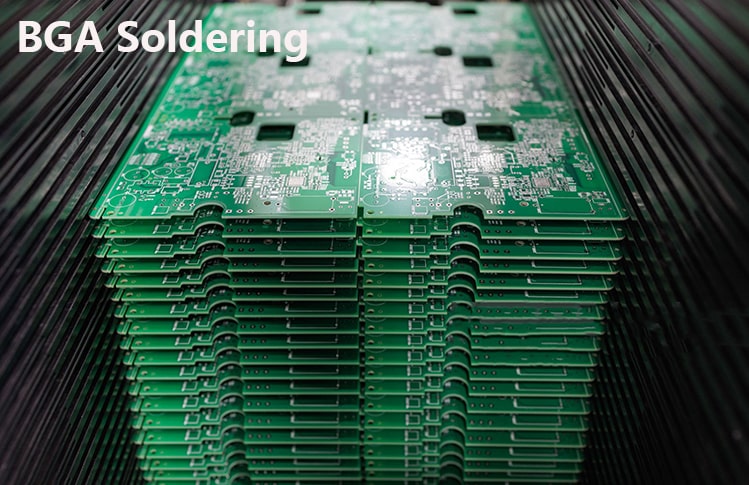

Automotive Control Board PCBA

BGA packages are widely used in automotive control boards due to their high density, stable electrical performance, and strong thermal reliability. However, BGA assembly also introduces specific challenges that must be addressed to ensure long-term stability in harsh automotive environments.

Key Challenges in BGA Assembly

Solder Volume Accuracy

Incorrect solder paste deposition—too much or too little—can cause weak joints, bridging, or inconsistent connections. This often results from improper stencil design or printing accuracy.

Component Misalignment

BGAs can shift during pick-and-place or reflow, especially larger automotive-grade packages. Even slight misalignment may lead to opens or short circuits hidden under the component.

Voids in Solder Joints

Voids reduce heat dissipation and weaken mechanical strength. For automotive electronics exposed to high temperatures, excessive voiding is unacceptable and must be tightly controlled.

Hidden Defects

BGA joints are fully concealed, making visual inspection impossible. Issues such as head-in-pillow, insufficient solder, or cold joints require advanced inspection methods to detect.

Our Solutions for Reliable BGA PCBA

Optimized Stencil Engineering

We design custom stencil apertures and thicknesses based on BGA pitch and ball size to achieve consistent solder paste volume.

High-Precision Placement

Advanced SMT equipment ensures accurate alignment, minimizing positional shift during placement and reflow.

Controlled Reflow Profiles

We create dedicated reflow curves for each automotive control board to reduce voids and ensure uniform wetting, including nitrogen reflow when required.

100% X-ray Inspection

All BGA assemblies undergo full X-ray inspection to identify voiding, misalignment, and hidden soldering defects.

Automotive-Grade Testing

Thermal cycling, vibration tests, and functional testing ensure every assembled control board meets long-term automotive reliability standards.

BGA technology is essential for modern automotive electronics, but its reliability depends on precise assembly and strict quality control. Through optimized processes, advanced inspection, and automotive-grade testing, we help global customers achieve stable and durable performance for their control boards.