How to Evaluate Whether an Overseas PCB Factory Is Truly Reliable

Choosing the right overseas PCB manufacturer is one of the most important decisions for any electronics company. A reliable factory does not just deliver boards on time—it protects your design, ensures consistent quality, and supports your business for the long term.

1. Certifications and Quality Systems

A professional PCB manufacturer should follow international quality standards. At minimum, look for:

ISO 9001 for quality management

UL certification for safety compliance

IATF 16949 if you produce automotive electronics

ISO 14001 for environmental management

These certifications show that the factory meets established process controls and is regularly audited by a third-party authority. Always ask for valid certificates, not only the logos.

2. Manufacturing Capabilities and Technical Depth

A reliable PCB partner should be transparent about what they can build and where their limits are.

Minimum trace/space

Controlled impedance capability

Available copper thickness

HDI, blind/buried vias, via-in-pad options

Materials supported (FR4, high-frequency laminates, Rogers, polyimide, etc.)

Factories with incomplete or outdated capability sheets are often not operating at the level required for today’s high-density or high-speed designs.

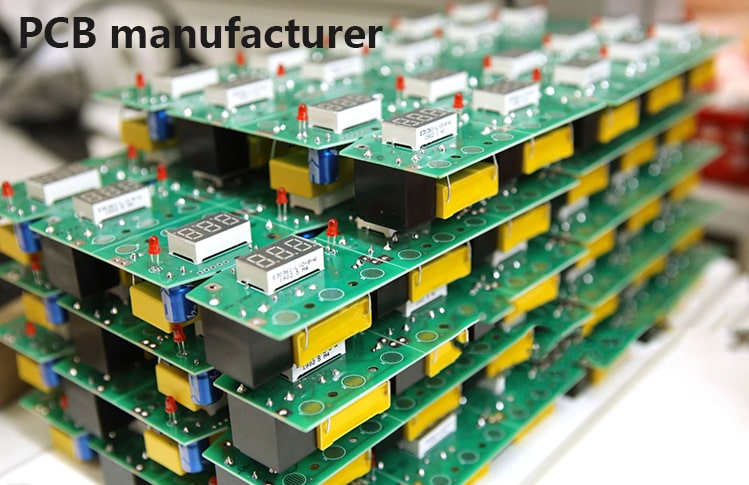

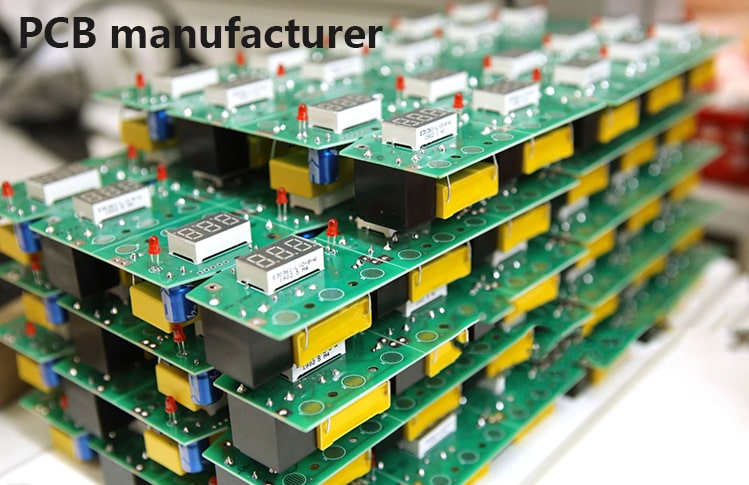

3. Equipment and Production Line

The quality of a PCB depends heavily on the equipment in the factory. When evaluating a supplier, check whether they use:

Automated exposure machines

Laser drilling for HDI

AOI and flying-probe testers

X-ray inspection

CNC routing and V-cut machines

Modern equipment means higher accuracy, fewer defects, and more stability in mass production. Many reputable suppliers provide photos or virtual factory tours—use this to assess whether the production line looks organized and up-to-date.

4. Quality Control and Testing

A reliable factory will always prioritize quality control. Ask how they manage:

Incoming material inspection (IQC)

In-process inspection (IPQC)

AOI for every inner and outer layer

Electrical testing before shipment

Final inspection and packaging

If the factory cannot clearly explain each step of their QC process, it is a sign of potential risk.

5. Engineering Support and Communication

Strong engineering support is often the difference between a smooth project and weeks of delay. A reliable PCB manufacturer should offer:

DFM (Design for Manufacturability) review

Gerber file checking

Stack-up consultation

Quick and clear technical communication

For overseas buyers, responsiveness is especially important. Evaluate the supplier’s communication speed during the quotation stage—it often reflects how they will support you after production begins.

6. Delivery Performance and Supply Chain Stability

On-time delivery is critical for global buyers. Ask for:

Average lead times for prototype and mass production

Record of on-time delivery rate

Material sourcing partners (e.g., Isola, Shengyi, Rogers)

Stable material suppliers and consistent schedules indicate a mature factory with good management.

7. Customer Reviews and Industry Reputation

Finally, check the factory’s track record:

Customer testimonials

Case studies

Years in the PCB industry

Whether they serve well-known brands

A manufacturer with long-term international clients is usually more reliable than a factory offering low prices but little history.

Conclusion

Evaluating a PCB factory is not only about price—it is about capability, communication, consistency, and trust. A reliable overseas PCB manufacturer will be transparent, technically strong, and committed to helping your product succeed in the market. Taking the time to assess these factors will protect your project from costly mistakes and help you build a long-term manufacturing partnership.