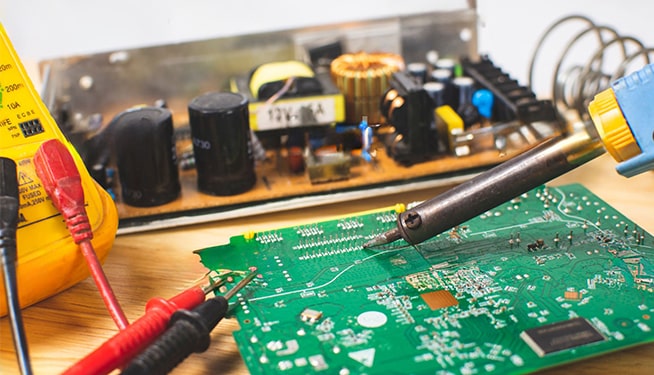

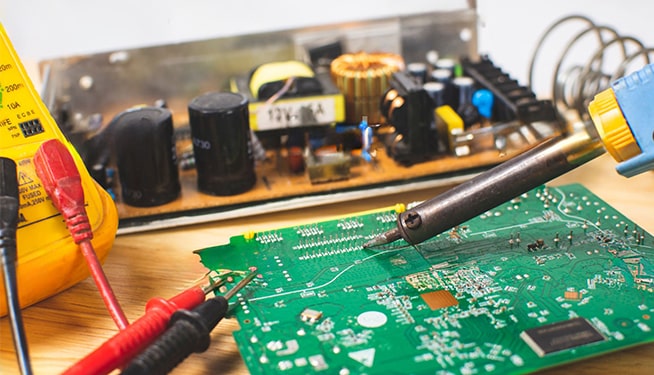

Preheating before PCBA welding

One -stop PCBA manufacturers today will tell you what the preheating before PCBA welding is? The reasons for preheating before PCBA processing should be preheated. In the large -scale production and welding environment, the importance of temperature distribution has been widely understood. Slow heating and preheating phase helps activate the welding to prevent heat shock, and improve the quality of the welding joints during SMT. However, when it involves rework, prototype production, or the first proofing item of PCBA, it is easy to forget the importance of the preheating phase, which may cause device damage, even if the device is not damaged. So, for such an important step, why is it often forgotten in the actual operation of the SMT processing plant? What are the consequences of omitting this stage?

What are the preheating before PCBA welding?

When technicians and practitioners heard the words "temperature curve" or "temperature curve", they would think of SMT backwing welding. The huge length along the welding area can easily see the four main temperature control areas, which will eventually produce a perfect welding point, hoping to do so. Through the experience of technical personnel and repeated experiments, carefully control and improve each stage. At each stage, it plays a role in improving the quality of welding joints and reducing defects. However, other industrial welding machines may not have such fine temperature control. But their common point is the warm -up stage.

Selective peak welding burn in welding

The function of the preheating phase is to increase the temperature of the entire component from the room temperature to maintain the temperature below the welding balm melting point, that is, about 150 ° C. Adjust the temperature change to maintain a constant slope of several degrees per second. After the preheating phase, the average thermal stage will be kept temperature in the heat stage to ensure that the circuit board is uniformly heated within a period of time. Then there is the backflow stage to start the formation of welding joints. During the preheating and soaking phase, the volatile solvents in the welded paste were burned and the welded agent was activated.

What is the preheating before PCBA welding?The knowledge points of preheating before PCBA prototype, want to learn more,You can follow PCBAMAKE. If you need to learn more about PCB prototype, SMT patch, PCBA processing related technical knowledge, please leave a message to get it!