Why use conformal coating on PCBA

What is PCB conformal coating?

Conformal coating is a polymer film applied to a PCB to protect the board and its components from the environment and corrosion. The film conforms perfectly to the shape of the PCB and can be applied to the part and conform to the topography. Each coating has unique chemistry and can be customized for specific protective properties. To protect all solder joints, electronic component leads, exposed traces, and any other areas prone to corrosion.

Why is conformal coating needed?

Conformal coatings are very necessary for PCBs and PCBAs that must work in harsh environments. PCB protective coating can protect circuit boards from corrosion, moisture and dust, and extend the shelf life of electronic products to ensure their performance and reliability. So, when you apply a conformal coating to a PCBA, you extend and improve its operating life, prevent premature PCBA failure, and help improve performance in a variety of harsh environments.

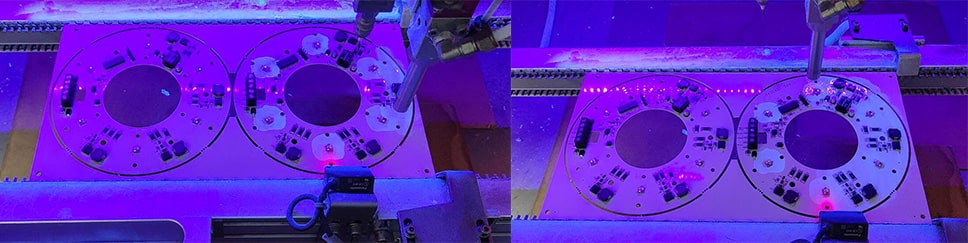

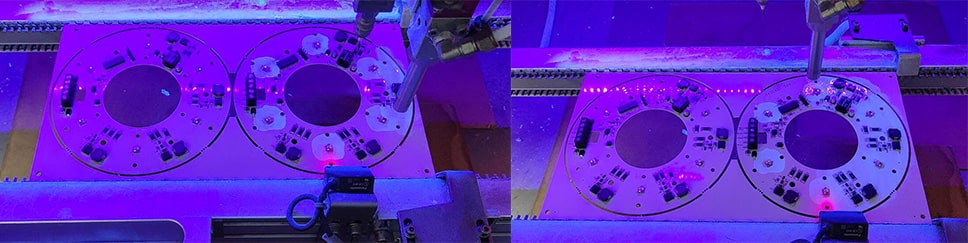

Conformal coating process

Conformal coatings only work well if the components are clean and free of physical defects, there must be no impurities including dust, debris or moisture on the component surface, and the coating itself must be uniform.

The usual sequence of operations is to test board functionality first, then tape or mask off areas that do not require coating. If the application allows, this can be done using temporary templates or basic tape. Then spray the coating in an even thickness and wait until dry.