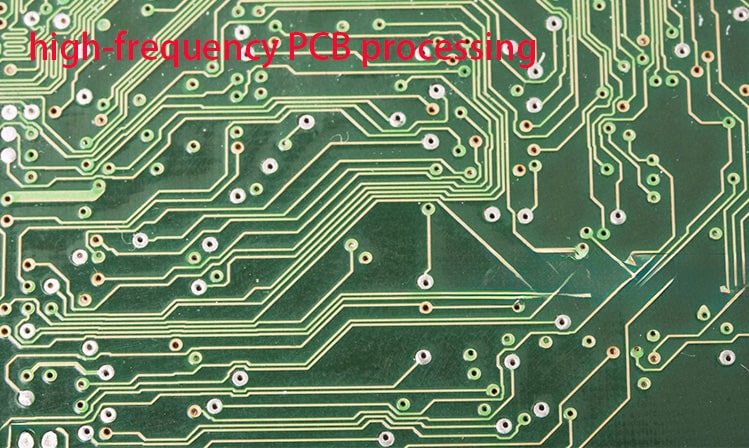

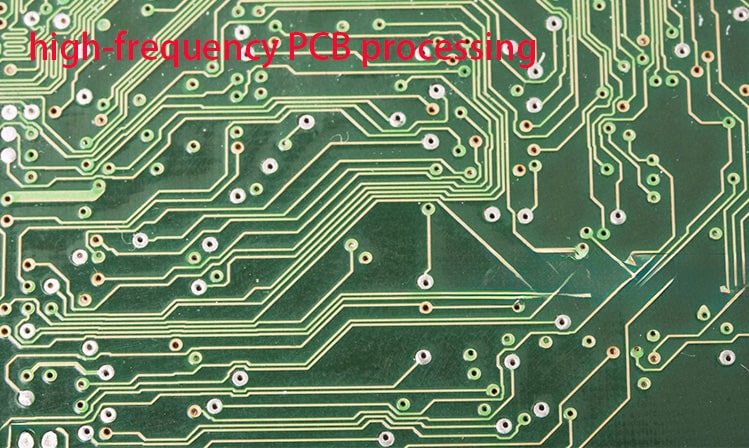

How to ensure the dimensional accuracy of circuit boards in high-frequency PCB processing

In the high-frequency PCB circuit board processing process, dimensional accuracy is a crucial factor. If not guaranteed, it will have a great impact on the quality and performance of the entire electronic device. So, how to ensure the dimensional accuracy of high-frequency PCB processing processes?

Select high-quality raw materials

In the process of high-frequency PCB processing, the selection of raw materials is a very critical link. High-quality raw materials can bring better circuit board materials and performance, thereby helping to ensure dimensional accuracy. When selecting raw materials, we need to pay attention to the following aspects:

1. The quality and durability of the material.

2. Dimensional accuracy and stability of the material.

3. The impact of materials on the impedance, signal transmission and other characteristics of electronic equipment.

Use high-precision processing technology

In addition to high-quality raw materials, the use of high-precision processing technology is also a necessary condition to ensure dimensional accuracy. In the process of circuit board processing, all links need to cooperate with each other to ensure the stability and accuracy of the entire processing process.

1. Accuracy of circuit board design.

2. Positioning accuracy of the inner layer board.

3. Control drilling accuracy and positioning accuracy.

4. Control cutting accuracy and positioning accuracy.

Strict quality control

In the process of circuit board processing, strict quality control is the key to ensuring dimensional accuracy. Throughout the entire processing process, we need to conduct multiple inspections and measurements to ensure that the scale of each link can accurately meet the requirements. During the quality control process, we need to pay attention to the following aspects:

1. Accuracy and precision of detection and measurement equipment.

2. Conduct quality inspections for each link.

3. Measure the stability and accuracy of the entire processing process.

In short, dimensional accuracy is a crucial factor in the circuit board processing process. Only through high-quality raw materials, high-precision processing technology, and strict quality control can the quality and performance of the entire electronic device be guaranteed.