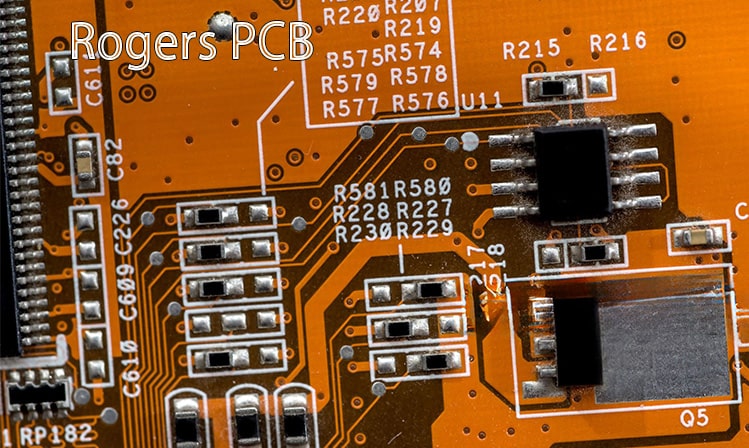

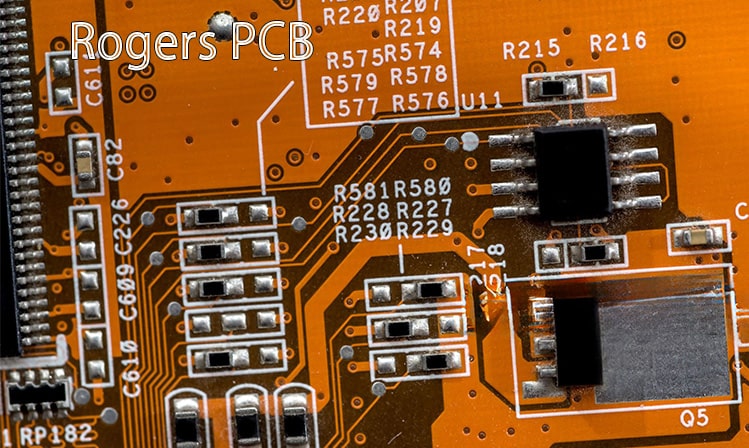

Rogers PCB

Many people have heard of Rogers PCB, but they don’t know what Rogers PCB is, its specific characteristics and its applicable range.Today I will tell you about Rogers PCB as I understand it.Rogers PCB board material is a high-frequency board model produced by Rogers Company. It is different from conventional PCB board epoxy resin. Rogers PCB does not have glass fiber in the middle and is a ceramic-based high-frequency material.

The difference between Rogers material and FR-4 material

1. Compared with FR-4 materials, Rogers materials are more expensive;

2. Compared with FR-4 materials, Rogers PCB materials have a lower dissipation factor (DF), so the signal loss is smaller;

3. Compared with FR-4 materials, Rogers PCB materials have a wider Dk (dielectric constant) range than FR-4 materials, and therefore have higher impedance stability;

4. Compared with FR-4 materials, Rogers PCB has extremely low water absorption, making it an ideal choice for applications in high-humidity environments;

5. Compared with FR-4 materials, Rogers PCB materials also improve impedance control in a better way;

6. Compared with FR-4 materials, Rogers PCB materials have better thermal management. In high-speed applications, the PCB generates a lot of heat, which must be handled by a good thermal management system, and FR4 PCBs cannot handle high temperatures.

Why choose Rogers PCB

With the rapid development of 5G technology, more and more devices require high-performance high-frequency PCBs and RF PCBs, and these PCBs require low signal loss and low electrical noise.

Rogers Substrate PCB is the most stable material in the industry. Based on overall performance, Rogers High Frequency PCB performed well. FR4 PCB is best suited for the best environments in low and medium frequency applications. They are rugged, have an excellent balance of electrical stability, and can be easily manufactured in almost all existing processes in the PCB industry. Roger high-frequency PCBs are suitable for high-quality performance in niche areas such as space applications. Temperature constancy and low outgassing properties make them an excellent choice for critical applications such as space and aerodynamics.

Application of Rogers PCB

Rogers PCB boards are widely used in many fields because of their unique performance and stability.

1. Communication technology field

Rogers PCB boards play an important role in communication equipment. It is widely used in high-frequency equipment such as 5G communication base stations, satellite communication equipment, and high-frequency antennas. Because Rogers PCB boards have low loss and stable dielectric properties, they can meet the requirements for high-frequency signal transmission and ensure the efficient operation of communication equipment in complex environments. At the same time, its thermal stability is also an important advantage in communication equipment, which can prevent device damage caused by temperature changes.

2.Military industry and aviation field

In the field of military aviation, Rogers PCB boards are widely used in key equipment such as aircraft, radars, satellites, and missiles. Their high strength and high temperature resistance allow these devices to maintain stable operation under extreme conditions, providing strong support for the national defense industry. At the same time, Rogers sheets also have excellent electromagnetic shielding properties, which can effectively suppress electromagnetic interference and ensure the reliable operation of aerospace and military equipment.

3. Medical equipment field

In the field of medical equipment, Rogers PCB boards also play an indispensable role. It is used in medical monitoring instruments, pacemakers, MRI and other equipment. Its high stability and reliability ensure the accuracy and safety of medical equipment.

4. Automotive electronics field

With the continuous development of automotive electronics technology, Rogers PCB boards have also been widely used in vehicle navigation, audio, body control and other aspects. Its excellent mechanical strength and thermal stability enable automotive electronic systems to operate stably in complex and changeable vehicle environments, improving the safety and comfort of the vehicle.

Corresponding advantages of Rogers PCB series

Rogers PCB RO3000 series: mainly provides excellent electrical performance and stable mechanical performance at a very competitive price. Rogers RO3000 series laminates without fiberglass reinforcement provide more unique isotropic electrical properties than competing materials. RO3006 has the same mechanical properties as RO3000™ series laminates and is suitable for hybrid design with epoxy glass cloth FR4 multilayer board circuits.

Widely used in commercial microwave radio frequency: automotive electronics millimeter wave radar, global positioning system satellite antenna, cellular communication system power amplifier and antenna, wireless communication patch antenna, live broadcast satellite, cable system data link, remote meter reading and power backplane wait.

Rogers RO4000 series: high frequency performance and low circuit board production cost. It has low loss, oxidation resistance that is 10 times higher than traditional thermoset materials, excellent electrical properties that can meet higher operating frequency applications, and remains stable throughout the circuit processing temperature range.

Widely used in automotive radars and sensors; point-to-point microwave transmission; amplifiers; phased array radar; radio frequency components.

PCBAmake can make mixed voltage/pure voltage multi-layer boards to meet the needs of high-frequency circuits. PCBAmake also has a variety of surface technologies: including hard gold-plated fingers, electro-thick gold, electro-soft gold, immersion silver, immersion tin, nickel-palladium gold, OSP + electro-gold, OSP + hard gold-plated fingers, spray tin + hard gold-plated fingers, Spray tin + electro-gold, etc.