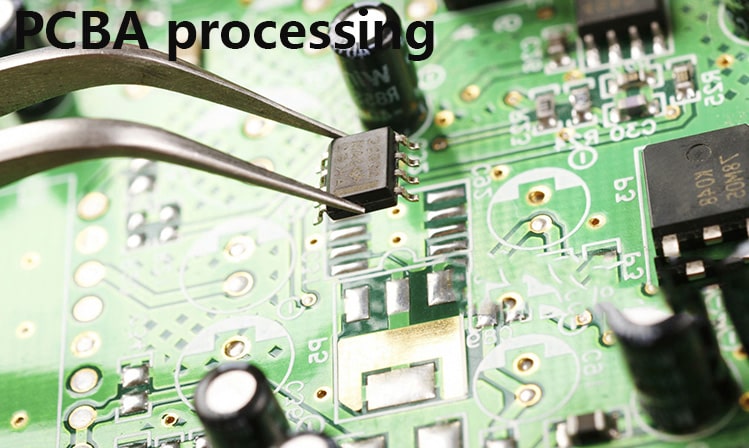

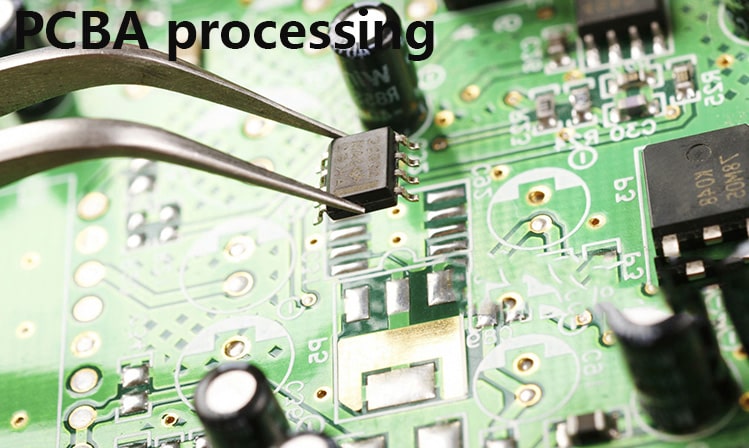

How to reduce deformation problems during PCBA processing

During PCBA processing, board deformation is a common but not negligible problem. Board deformation can lead to poor component welding, circuit short circuit and other quality problems, affecting production efficiency and product performance.

1.The main reasons for PCBA board deformation

Material properties:

The thermal expansion coefficient of the PCB substrate is inconsistent, resulting in internal stress during thermal processing.

Multilayer boards are not aligned during lamination, resulting in stress concentration.

Production process:

Unreasonable welding process, such as improper control of reflow soldering and wave soldering temperature curves.

Asymmetric layout and uneven copper foil distribution lead to unbalanced thermal stress.

Equipment settings:

The heating and cooling rates of the reflow oven are too fast.

The precision of the pressing and cutting equipment is insufficient.

Environmental factors:

The humidity and temperature of the production environment fluctuate greatly.

PCB boards stored in an unsuitable environment for a long time are prone to moisture absorption, resulting in deformation.

2. Solutions to reduce PCBA board deformation

Material selection and design optimization

Choose high-quality substrates with low thermal expansion coefficients, such as high TG value (glass transition temperature) materials.

Optimize PCB design to ensure uniform distribution of copper foil and avoid large blank areas.

When designing multi-layer boards, ensure symmetry and reduce the generation of internal stress.

Process optimization

Reflow control:

Reasonably set the temperature curve to avoid too fast heating and cooling processes.

Use preheating zone to improve the overall temperature uniformity of PCB.

Wave soldering process improvement:

Control the wave soldering transmission speed and temperature to ensure the quality of solder joints.

Add support devices to prevent bending during welding.

Equipment accuracy improvement

Use high-precision lamination and cutting equipment to avoid residual stress during manufacturing.

Regularly maintain reflow equipment to ensure stable temperature zones and prevent temperature overshoot.

Environmental control and storage management

Environmental control:

The production workshop maintains a constant temperature and humidity environment, and the humidity is controlled at 40%-60%.

Install temperature and humidity monitoring equipment to monitor the production environment in real time.

Storage management:

Avoid long-term exposure to humid air before PCBA processing.

Use moisture-proof bags and vacuum packaging during storage to prevent moisture absorption and deformation.

3.Implementation and quality assurance measures

Quality inspection: Carry out board flatness inspection at each stage of production to ensure that defective products are screened out in time.

Process improvement team: Establish a professional team to regularly evaluate and optimize the process.

Continuous training: Provide equipment operation and quality control training to ensure the technical level of employees.