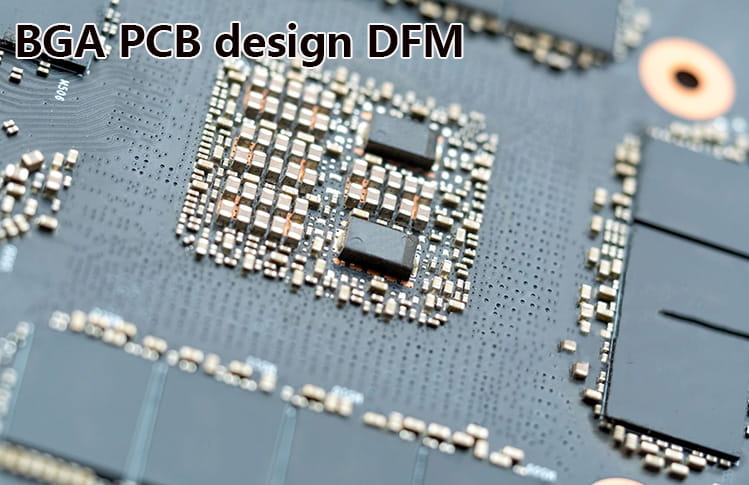

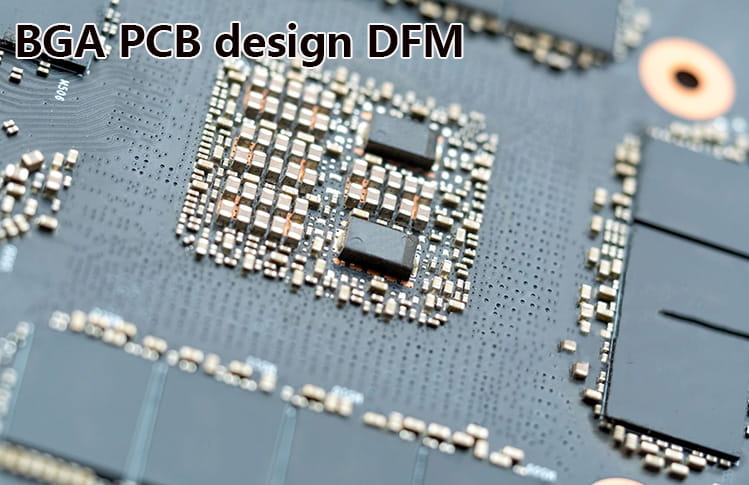

BGA PCB Design DFM: Manufacturing Risks and Optimization Strategies

BGA packages enable high I/O density but also introduce significant manufacturing risks.

In many cases, BGA soldering issues originate from PCB DFM weaknesses, not assembly errors.

Common Manufacturing Risks in BGA PCB Design

Insufficient solder mask clearance

Improper via-in-pad implementation

Inconsistent thermal balance

Without proper DFM, these issues often surface during mass production.

Critical DFM Considerations for BGA PCBs

1. Via-in-Pad Design Decisions

Via-in-pad can improve routing density but requires:

Proper copper filling

Planarization control

Incorrect implementation leads to solder voiding and reliability problems.

2. Solder Mask Design for High-Density BGAs

Extremely narrow solder mask bridges increase:

Risk of solder bridging

Mask misalignment defects

DFM recommends maintaining manufacturable solder mask openings, even if it slightly increases layout area.

3. Thermal Balance and Warpage Control

Uneven copper distribution under BGAs may cause:

Warpage during reflow

Head-in-pillow defects

Balanced copper design improves both assembly yield and long-term reliability.

4. Inspection and Rework Accessibility

High-end BGA designs should consider:

AOI and X-ray inspectability

Rework feasibility

Designing for inspection is a critical but often overlooked DFM factor.

👉 Related reading: High Precision PCB DFM Checklist

BGA DFM as a Reliability Strategy

For products requiring long lifecycle stability, BGA DFM directly impacts field reliability.

Well-planned DFM reduces rework dependency and improves overall manufacturing confidence.