Common Types of Conformal Coatings

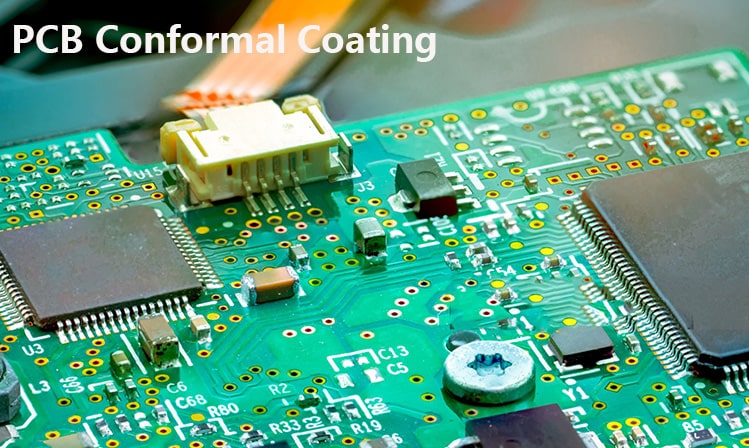

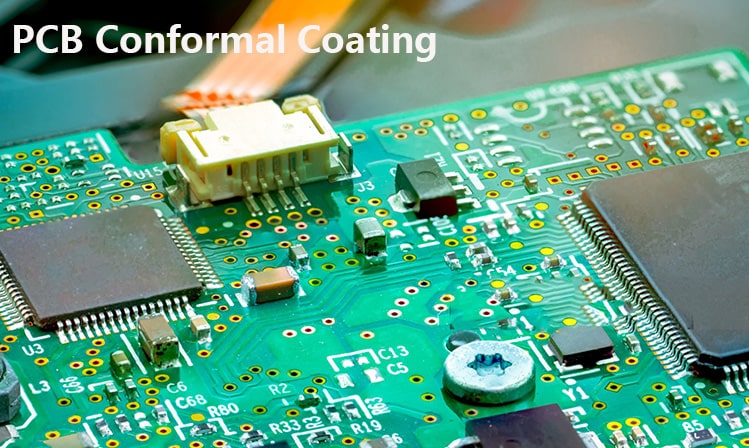

A Guide to Conformal Coatings for PCB Protection

In PCB manufacturing, pcb conformal coatings (also known as PCB protective coatings) are essential for safeguarding circuits against moisture, dust, chemicals, and other environmental hazards. Choosing the right coating ensures long-term reliability, especially in harsh conditions.

This guide covers the most common types of conformal coatings and how to select the best one for your application.

Common Types of Conformal Coatings

1. Acrylic (AR) – The All-Rounder

✔ Fast drying (air-cures quickly)

✔ Easy to rework (can be removed with solvents)

✔ Good moisture & UV resistance

✖ Limited chemical & high-temperature resistance

✅ Best for: Consumer electronics, LED lighting, and general-purpose PCBs.

2. Polyurethane (UR) – The Chemical Shield

✔ Excellent chemical & solvent resistance

✔ Strong moisture protection

✔ Durable & abrasion-resistant

✖ Harder to remove for repairs

✅ Best for: Automotive, marine, and industrial electronics exposed to oils, fuels, or solvents.

3. Silicone (SR) – The Extreme Performer✔ Wide temperature range (-50°C to 200°C+)

✔ Highly flexible (great for thermal cycling)

✔ Excellent waterproofing

✖ Lower mechanical strength & can attract dust

✅ Best for: High-temperature environments (e.g., engine control units), outdoor electronics, and LED drivers.

4. Epoxy (ER) – The Tough Protector✔ Hard, durable finish (great for mechanical protection)

✔ Superior chemical & moisture resistance

✔ Strong adhesion

✖ Almost impossible to rework

✅ Best for: Harsh industrial environments where maximum protection is needed.

5. UV-Cure – The Fast Solution✔ Cures in seconds under UV light

✔ Low VOC, eco-friendly options

✔ Precise application (selective coating)

✖ Shaded areas may not cure properly

✅ Best for: High-volume production with fast turnaround needs.

How to Choose the Right Conformal Coating?1. Consider the Operating Environment

Humid or wet conditions? → Polyurethane or Silicone

High temperatures? → Silicone

Chemical exposure? → Polyurethane or Epoxy

Need flexibility? → Silicone

2. Check Electrical & Thermal Requirements

Some coatings offer better insulation or heat dissipation.

3. Evaluate Rework Needs

If frequent repairs are expected, choose Acrylic (easy to remove).

For permanent protection, Epoxy is best.

4. Production Process Matters

Fast curing? → UV or Acrylic

Precision coating? → Selective spray or UV

Dipping or brushing? → Thicker coatings like Epoxy

5. Compliance & SafetyEnsure the coating meets IPC, UL, or RoHS standards for your industry.

The right conformal coating extends PCB lifespan and prevents failures in harsh environments.

Acrylic → Best balance of protection & reworkability

Polyurethane → Superior chemical resistance

Silicone → Extreme temperature performance

Epoxy → Maximum durability

UV-Cure → Fast, eco-friendly option

Need help selecting the best coating for your PCB? Contact our experts today!