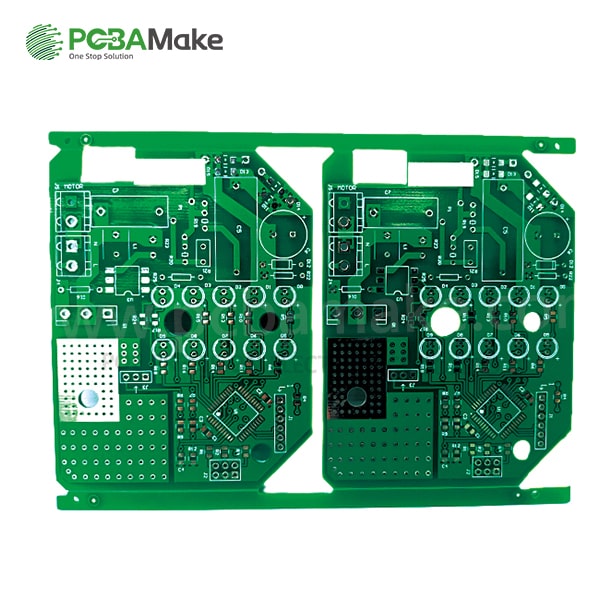

Power Control PCBA

For the research and development of switching power supply, Power Control PCB assembly design occupies a very important position. A poor PCB has poor EMC performance, high output noise, weak anti-interference ability, and even basic functions are defective.

Slightly different from other hardware circuit PCBs, Power Control pcb have some of their own characteristics

High output stability:

Due to the fast response speed of the system (microsecond level), it has strong adaptability to grid power and load changes, and the output accuracy can be better than 1%. The working efficiency of the Power Control pcb assembly is high, so the control precision is high, which is conducive to improving product quality.

Good energy saving effect:

Due to the high-frequency transformer used in the Power Control pcb assembly, the conversion efficiency is greatly improved. Under normal circumstances, the efficiency is improved by more than 10% compared with the thyristor equipment, and when the load rate is below 70%, the efficiency is improved by more than 30% compared with the thyristor equipment.

Small size and light weight:

The volume and weight of the Power Control PCB assembly are 1/5-1/10 of the thyristor PCB power supply, which is convenient for you to plan, expand, move, maintain and install.