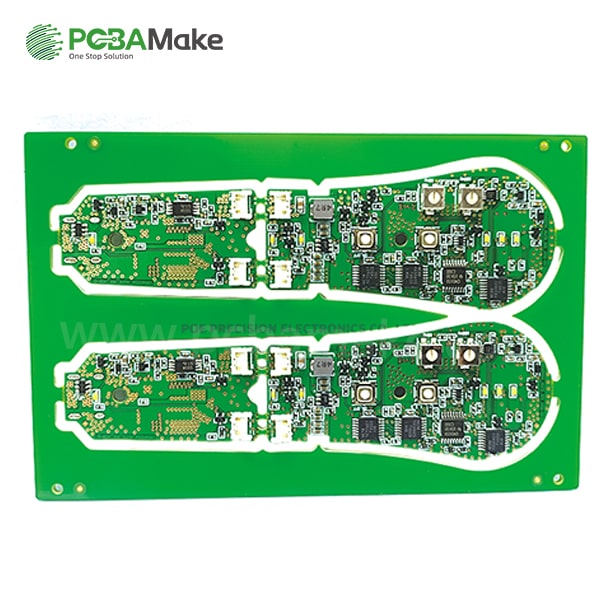

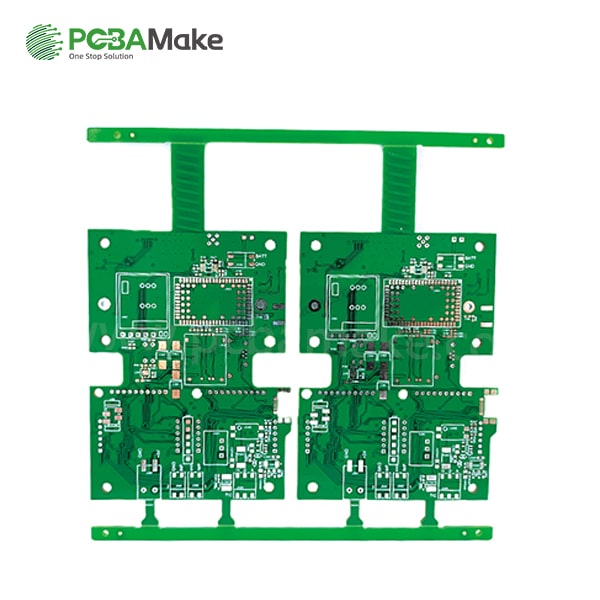

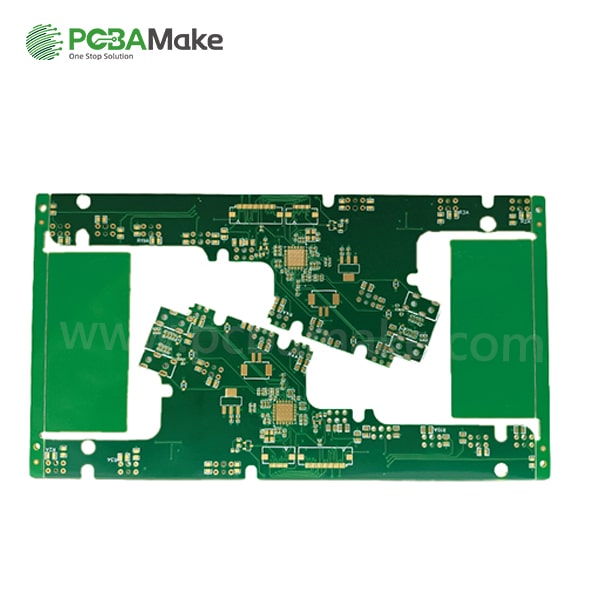

Robot PCBA

With the gradual decline of the demographic dividend and the rising labor costs of enterprises, industrial robots are gradually entering the public eye.

As a labor-intensive industry, how to control costs, solve yield and yield problems, and realize automation and intelligent manufacturing in the production process has become particularly important.

The introduction of robots into the production process of the PCB industry can greatly improve production efficiency and allow manufacturers to occupy the market more quickly

Advantages of Robot PCBA Automation Equipment

1. Reduce labor, speed up work rhythm, and improve work efficiency. Robot pcb can achieve high-speed repetitive operations, which can be much higher than manual work rhythms, thus bringing about a substantial increase in work efficiency and a reduction

2. Improve operation accuracy and product quality.Robot PCB automation equipment can use programming and vision systems to achieve accurate positioning and repeatability, effectively improving product quality.

3. Effectively reduce material consumption rate.

4. The use of Robot PCB automation equipment can avoid potential threats to workers' health and safety in the working environment, saving investment in environmental safety.

5. The manufacturing process can be made flexible. In the future, there will be more and more small batch orders in the Robot PCB industry. The use of automated equipment can greatly improve the flexibility of production and achieve rapid delivery of orders

6. Reduce the efficiency and quality decline and accident rate caused by the impact of repetitive and boring processes on workers' status.

7. Optimize the Robot PCB operation process and reduce the space occupied by production operations.

8. Significantly reduce the error rate of manual operation, making the production line smoother and more efficient.

9. Enhancement of brand image and reputation. The application of industrial robots has further improved the automation level of PCB manufacturers, driving the overall competitiveness of manufacturers in the industry.

Robot PCB automation equipment realizes real production automation, quality automation, and benefit automation for customers, reduces labor costs, improves production efficiency, and improves product quality.