What are the PCBA functional tests?

Printed circuit board assembly (PCBA) functional testing is a key step to ensure the performance and reliability of electronic products.

What is PCBA functional testing?

PCBA functional testing is a comprehensive inspection of the assembled and soldered pcba circuit board. By conducting PCBA testing, manufacturers can detect and correct defects in the PCBA production process, ensure product quality and reliability, and improve product production efficiency and reduce manufacturing costs. Usually, functional testing is performed at the last stage of circuit board production to ensure that the circuit board works properly in the final end product.

The main PCBA functional tests are as follows

1. Electrical performance test

Electrical performance testing is the core of functional testing, which mainly includes the following aspects:

Voltage test: Ensure that each voltage point on the circuit board meets the design specifications.

Current test: Detect whether the current value of each circuit is within the normal range.

Resistance test: Check the resistance value on the circuit board to ensure that there is no short circuit or open circuit.

Signal integrity test: Verify the integrity of signal transmission and check whether there is signal attenuation or distortion.

2. Functional verification test

Functional verification test is used to confirm whether the specific functions of PCBA are working properly. Depending on the design and purpose of the board, functional verification testing may include:

Microcontroller testing: Ensure that the microcontroller can start and run correctly and verify its pin functions.

Communication interface testing: Test the operation of communication interfaces such as UART, SPI, I2C, etc.

Sensor testing: Check whether the response of various sensors (such as temperature sensors, pressure sensors, etc.) is normal.

Module testing: Verify the functionality of wireless modules such as Wi-Fi and Bluetooth.

3. Power testing

Power testing mainly detects the power consumption of the PCBA in different working states, including standby power consumption and working power consumption. This helps to evaluate the energy efficiency and power management performance of the board.

4. Environmental adaptability testing

Although strictly speaking, environmental adaptability testing is more of a reliability test, it is also performed in functional testing in some cases. For example:

Temperature cycling test: Test the operation of the board in different temperature environments.

Humidity test: Verify the performance of the board in a high humidity environment.

Vibration test: Evaluate the reliability of the board under vibration conditions.

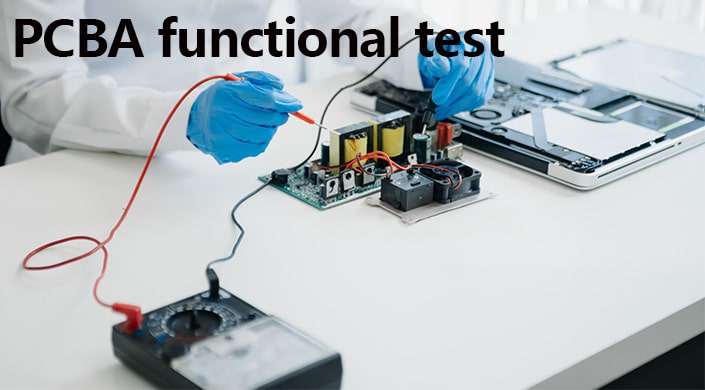

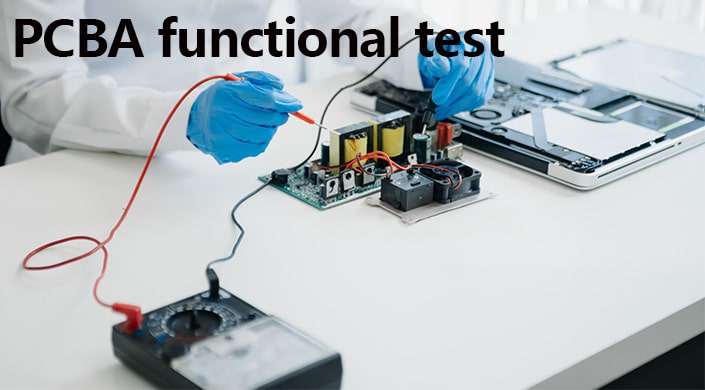

PCBA functional test process in SMT processing factory

Testing equipment and tools

In our own SMT processing factory, advanced testing equipment and tools are used to ensure the accuracy and reliability of the test, including:

Automatic test equipment (ATE): used for rapid electrical performance testing in mass production.

Oscilloscope: used for signal integrity and waveform analysis.

Power analyzer: measures the power consumption of the circuit board.

Environmental test chamber: used for temperature and humidity testing.

Testing steps

Preliminary inspection: Before functional testing, visual inspection and automatic optical inspection (AOI) are first performed to ensure that the circuit board has no obvious manufacturing defects.

Electrical performance test: Use ATE for voltage, current and resistance testing.

Functional verification test: According to the design of the circuit board, detailed tests of microcontrollers, communication interfaces, sensors and other functions are performed.

Power test: Measure the power consumption of the circuit board under different working conditions.

Environmental adaptability test (optional): Temperature, humidity and vibration tests are performed in specific projects.

Data recording and analysis

The data of each test step will be recorded in detail and analyzed by data analysis software. These data are not only used to determine whether the product is qualified, but also to optimize the production process and improve the design.

PCBA functional testing is a key link in ensuring the quality of electronic products. Through detailed electrical performance testing, functional verification testing, power testing and environmental adaptability testing, the performance and reliability of the circuit board can be fully evaluated. In the SMT processing plant, the use of advanced testing equipment and strict testing processes can effectively ensure that each circuit board meets the design requirements, thereby improving the quality of the final product and user satisfaction.