Panel Requirements for PCBA Assembly

PCBAMake is a full service printed circuit board manufacturer providing industry leading technology inPCB Fabrication, PCB Assembly and components soucing, additionly we also provide programming, funcational testing,case assembly and so on,we are one of China's leading companies in PCB/PCBA industry.

Today we are gonna talk about the Panel Requirements for PCBA Assembly.

1: What is panel creation.

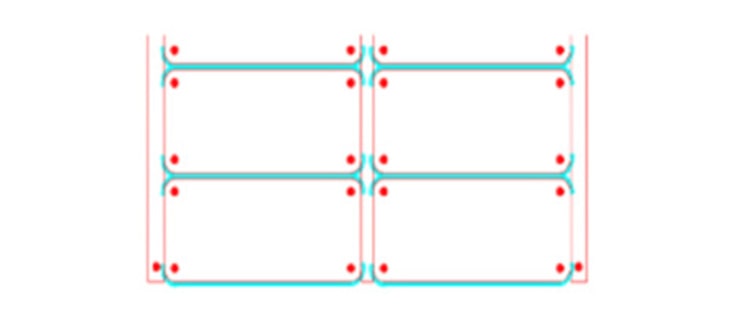

Panel creation means aggregating multiple PCBs on one large panel to manufacture. This large board is called a panel. Normally people will choose panel design for production, unless the board is too big for the panel or there are special requirements. It is easy to separate the multiple PCBs and avoid damaging the boards in the process of the panel assembly.

2: Why need panel design when manufacturing PCBs?

It offers several benefits:

First of all, Panel design is more suitable for automatic production line, and improve PCB manufacturing and assembly efficiency.

Secondly,Panelization protects the PCB from shock and vibration experienced during assembly and it can protects the boards from shipping as well,

In additionly,we recommend panel design for PCB manufacturing and assembly because panel production will also reduce production cost in a way. It provide convenience for SMT pcb assembly and testing,so we can save cost and time from production.

Generally PCB manufacturers provide you with panel service for free and also can produce the boards according to your panel design. There are several panel types for you to choose from, and all the panel techniques are easy for you to separate the boards into single boards.

3: We have different Panel types of PCB assembly:

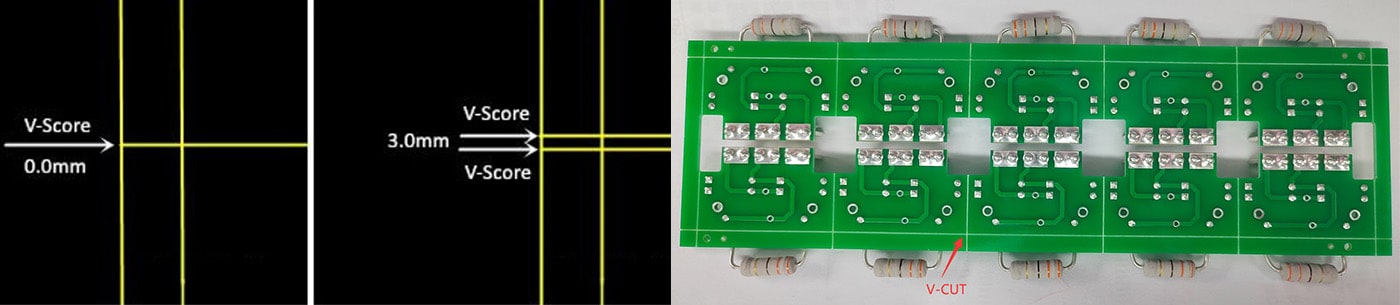

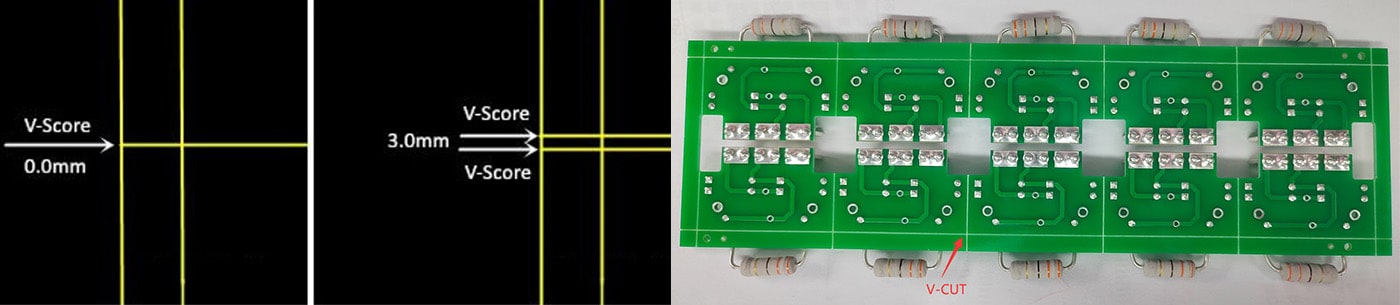

V-cut

There is a V-cut slot between the boards cut with a V-cut machine, which can be easily broken when used. V-cut is suitable for the regular shaped PCBs with straight edges because the V-scoring machine will go through the whole board without stopping when running.

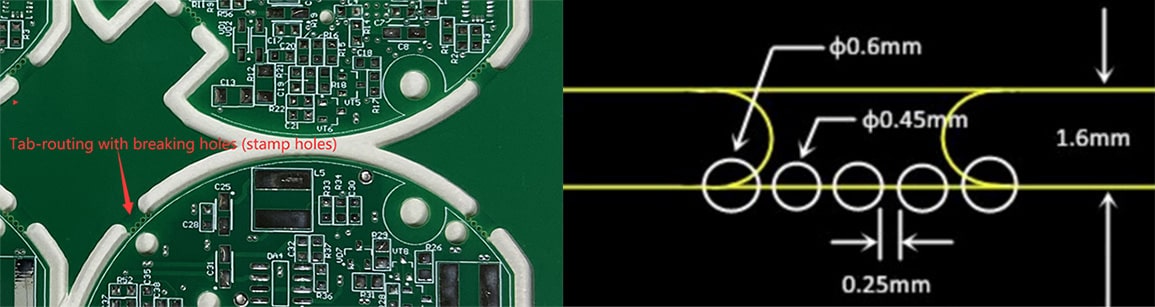

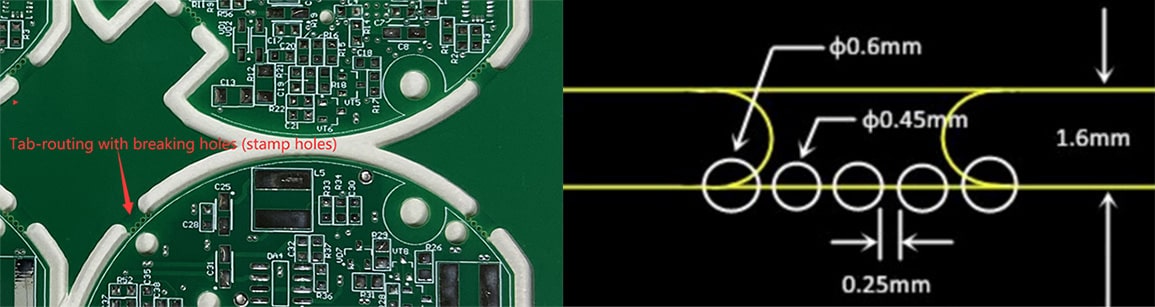

Tab-routing with breaking holes

PCB units with different sizes are also more suitable for Tab-routing. The edges of the two boards are connected by many small holes like stamp holes, which is easy to break.

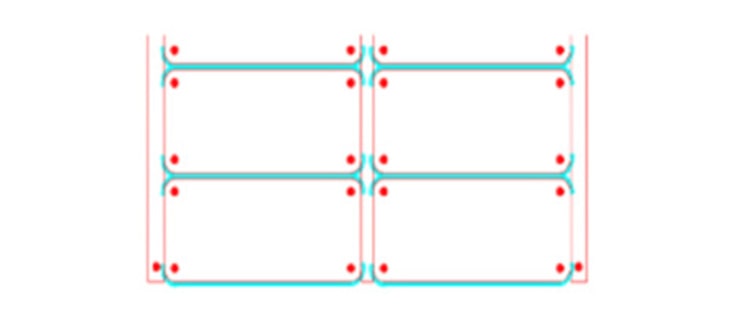

Panel with both V-Cut and tab routes

For the consideration of PCB manufacturing, sometimes there need both V-scoring and tab-routing techniques on one panel as well.

We have professional pcb engineers who will analyze these. If you have any questions about pcb manufacturing or pcba assembly and other processing, please feel free to keep in touch with us. We are a one-stop pcba assembly and processing factory that can meet all your needs, including components. From procurement to final delivery, etc.

Contact Us for a free quote.